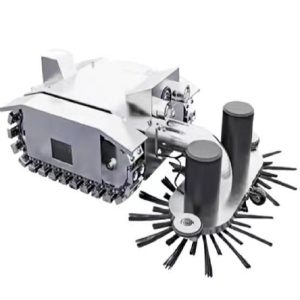

Round duct connecting machine

Round duct connecting machine

The core function of a round duct connecting machine is to process both ends of a pre-rolled and longitudinally welded round duct section into specific joint interface forms. Its working principle is primarily based on mechanical cold-forming processing. It uses molds to roll, bend, or stamp the metal sheet, forming it into a standardized connection structure.

The core function of a round duct connecting machine is to process both ends of a pre-rolled and longitudinally welded round duct section into specific joint interface forms. Its working principle is primarily based on mechanical cold-forming processing. It uses molds to roll, bend, or stamp the metal sheet, forming it into a standardized connection structure.

The core function of a round duct connecting machine is to process both ends of a pre-rolled and longitudinally welded round duct section into specific joint interface forms. Its working principle is primarily based on mechanical cold-forming processing. It uses molds to roll, bend, or stamp the metal sheet, forming it into a standardized connection structure.

La función principal de una máquina conectadora de ductos redondos es procesar ambos extremos de una sección de ducto redondo previamente conformado y soldado longitudinalmente, para darles formas de interfaz de unión específicas. Su principio de funcionamiento se basa principalmente en el procesamiento por conformación en frío mecánico. Utiliza moldes para rodar, doblar o estampar la chapa metálica, formando una estructura de conexión estandarizada.

| Thickness/Espesor | 0.4-0.7mm |

| Diameter/Diámetro | 76-355mm |

| Sheet width/Ancho de la hoja | 76mm or 152mm |

| Depth of cutting

Profundidad de pestañas cortada |

16mm standard, adjustable to19mm

16mm estándar, ajustable a 19mm |

| Width of cutting

Ancho de cortada |

Approx.19mm centers

Aprox.19mm centros |

| Working speed

Velocidad de trabajo |

0.3m/min |

| Power/Potencia | 380V/3Ph/50Hz,2.2KW |

| Dimension/Dimensiones | 890*650*1075mm |

| Weight/Peso | Approx.255kg |