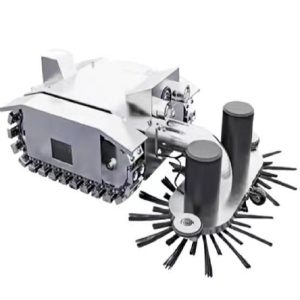

CNC Soft Connection Production Line

CNC Soft Connection Production Line

The CNC soft connection production line is a duct soft connection processing production line developed by our company’s professional technical personnel based on similar production lines abroad. It effectively improves work efficiency and product quality. It is currently a brand-new soft connection production line in China that is fully functional, has excellent performance, and a high degree of automation. The production speed of the entire line is adjustable from 0 to 8 meters, and its production efficiency is significantly higher than that of other similar equipment.

The CNC soft connection production line is a duct soft connection processing production line developed by our company’s professional technical personnel based on similar production lines abroad. It effectively improves work efficiency and product quality. It is currently a brand-new soft connection production line in China that is fully functional, has excellent performance, and a high degree of automation. The production speed of the entire line is adjustable from 0 to 8 meters, and its production efficiency is significantly higher than that of other similar equipment.

1. Material feeding system

– Automatic or manual unwinding mechanism for conveying flexible materials (such as fire-resistant fabric, rubber belts, etc.).

2. Forming mold

– Designed according to the shape of the flexible connection (circular, rectangular) to ensure uniform wrapping of the material around the flange or metal ring.

3. Pressing/Heat Sealing Mechanism

Mechanical pressing: Uses hydraulic or pneumatic pressure to securely bond the material to the flange.

High-frequency heat sealing (suitable for PVC/TPU-coated fabrics): Uses high-frequency heating to fuse the material, providing better sealing performance.

4. **Sewing system** (optional)

– Some models are equipped with industrial sewing machines to reinforce the edges of the soft connection.

5. Control system

– PLC or touchscreen control, allowing adjustment of parameters such as pressure, temperature (for heat-sealing models), and speed.

| Description | Unit | Parameters |

| Processing Thickness Range | MM | 0.4-0.7 |

| Galvanized iron sheet width | MM | 50-130 |

| Fireproof fabric width | MM | 100-300 |

| Finished width range | MM | 145-500 |

| Feed rate | M/MIN | 0.8 |

| Dimensions | MM | 3500X2000X1500 |

| Weight | KG | 3500 |