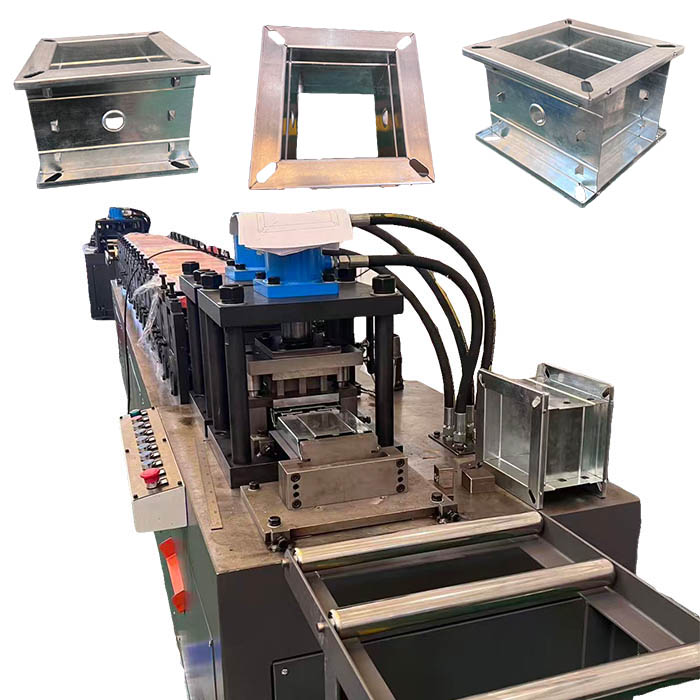

Air duct damper frame roll forming line

Air duct damper frame roll forming line

This production line is a highly automated, continuous roll forming system specifically designed for manufacturing the frame profiles of air control dampers used in Heating, Ventilation, and Air Conditioning (HVAC) systems.

The core process involves uncoiling a coil of raw material (typically galvanized steel, leveling it, and then progressively feeding it through a series of precision-engineered roll forming stations. Each set of rollers gradually bends the metal strip into the complex cross-sectional profile required for the damper blade—such as opposed-angle blades, double-channel blades, or blade-with-gasket profiles—in a single, continuous operation.

The line integrates subsequent processes like punching, notching, cutting-to-length, and sometimes automatic stacking, significantly enhancing production efficiency, dimensional accuracy, and consistency while reducing labor costs and material waste. It is the essential equipment for high-volume, high-quality damper manufacturing.

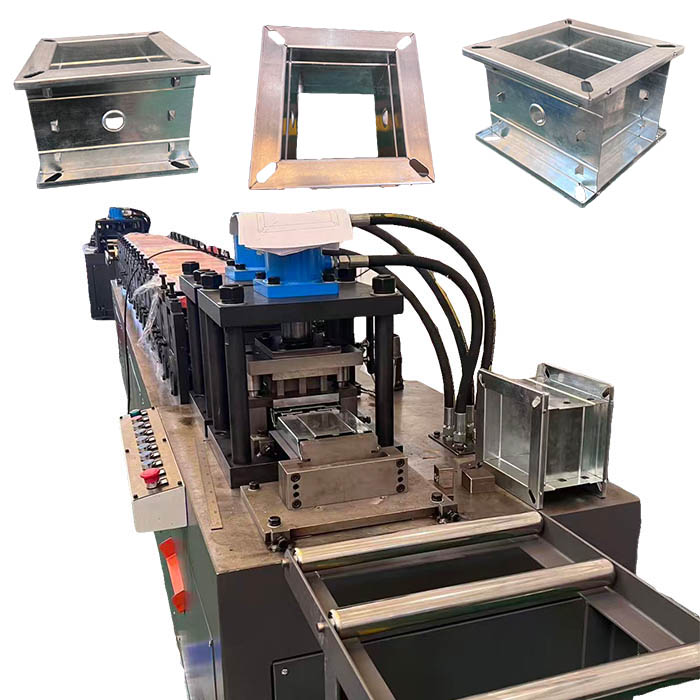

This production line is a highly automated, continuous roll forming system specifically designed for manufacturing the frame profiles of air control dampers used in Heating, Ventilation, and Air Conditioning (HVAC) systems.

The core process involves uncoiling a coil of raw material (typically galvanized steel, leveling it, and then progressively feeding it through a series of precision-engineered roll forming stations. Each set of rollers gradually bends the metal strip into the complex cross-sectional profile required for the damper blade—such as opposed-angle blades, double-channel blades, or blade-with-gasket profiles—in a single, continuous operation.

The line integrates subsequent processes like punching, notching, cutting-to-length, and sometimes automatic stacking, significantly enhancing production efficiency, dimensional accuracy, and consistency while reducing labor costs and material waste. It is the essential equipment for high-volume, high-quality damper manufacturing.

This production line is a highly automated, continuous roll forming system specifically designed for manufacturing the frame profiles of air control dampers used in Heating, Ventilation, and Air Conditioning (HVAC) systems.

The core process involves uncoiling a coil of raw material (typically galvanized steel, leveling it, and then progressively feeding it through a series of precision-engineered roll forming stations. Each set of rollers gradually bends the metal strip into the complex cross-sectional profile required for the damper blade—such as opposed-angle blades, double-channel blades, or blade-with-gasket profiles—in a single, continuous operation.

The line integrates subsequent processes like punching, notching, cutting-to-length, and sometimes automatic stacking, significantly enhancing production efficiency, dimensional accuracy, and consistency while reducing labor costs and material waste. It is the essential equipment for high-volume, high-quality damper manufacturing.

-

High Degree of Automation

-

Features an automatic decoiler, feed system, and programmable logic controller (PLC) with a human-machine interface (HMI). This allows for minimal manual intervention, from loading the coil to outputting finished, cut-to-length parts.

-

-

Precision Roll Forming

-

Utilizes a multi-stand roll forming mill with custom-designed carbide-tipped or hardened steel rollers. This ensures the precise and consistent formation of complex damper blade profiles with tight tolerances.

-

-

Integrated In-Line Punching & Notching

-

Equipped with synchronized servo-driven punching units that perforate holes for pivot rods, attachment points, or seals directly in the web of the profile during the forming process, eliminating secondary operations.

-

-

Servo-Driven Precision Cutting

-

Employs a high-precision servo fly-cut system or hydraulic cutoff that cleanly shears the continuously formed profile to pre-set lengths without deformation or burrs, ensuring every piece is identical.

-

-

Superior Material Handling

-

Includes a material leveler (straightener) to ensure flatness of the strip before forming, which is critical for final product quality. An automatic stacker or output conveyor is often included for orderly collection of finished parts.

-

-

Flexibility and Quick Changeover

-

Designed with modular tooling and quick-release mechanisms, allowing for relatively fast changes between different damper blade profiles and sizes to accommodate diverse production orders.

-

-

High Efficiency and Productivity

-

Capable of producing a high volume of finished damper blades (often tens of meters per minute) in a continuous operation, drastically outperforming traditional manual or semi-automatic methods.

-

-

Consistent and Superior Quality

-

Automation eliminates human error, ensuring every produced blade has identical dimensions, hole patterns, and mechanical properties, leading to better-performing and easier-to-assemble dampers.

-

-

Reduced Operational Costs

-

Minimizes labor requirements (often requiring only 1-2 operators) and significantly reduces material scrap compared to methods using pre-cut blanks.

-