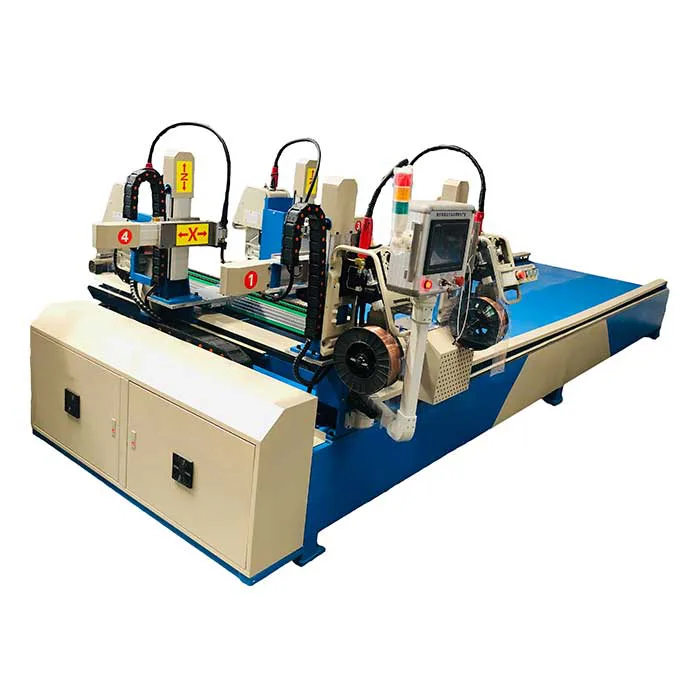

Air Duct Steel Flange Welding Machine

Air Duct Steel Flange Welding Machine

Duct steel flange welding machine is for the efficient and high capacity production work on the HVAC square and rectangular duct flange fabrication.

Duct steel flange welding machine composes with welding table, TIG welding and electronical control system.

Four clamper fix the four side of angle flange by pneumatic pistons, then four TIG welder do the welding at four edges on steel angle flanges through the mechanical arms moving on X and Z axis. After welding finished, the welding table will feed the welded product out of working zone. The size square and rectangular steel angle flanges can be adjusted from minimum 200x200mm to maximum 5000x1500mm.

Duct steel flange welding machine is for the efficient and high capacity production work on the HVAC square and rectangular duct flange fabrication.

Duct steel flange welding machine composes with welding table, TIG welding and electronical control system.

Four clamper fix the four side of angle flange by pneumatic pistons, then four TIG welder do the welding at four edges on steel angle flanges through the mechanical arms moving on X and Z axis. After welding finished, the welding table will feed the welded product out of working zone. The size square and rectangular steel angle flanges can be adjusted from minimum 200x200mm to maximum 5000x1500mm.

Large flat high-precision welding table ensures the welding accuracy of steel duct flange.

The operating system controls the cylinder according to the flange size in the program instructions to tighten the duct angle steel flange material for welding.

Four welding torches simultaneously weld angle steel flanges to ensure the flatness and verticality of flange welding.

Four welding torches automatically return after the welding step is completed to wait for the next welding.

Right angle welding route of torches fits the angle steel air duct flange welding to ensure the welding quality.

High-quality Panasonic TIG welding machine guarantees welding quality.

The conveyor belt automatically sends the product out of the table after the welding step is completed.

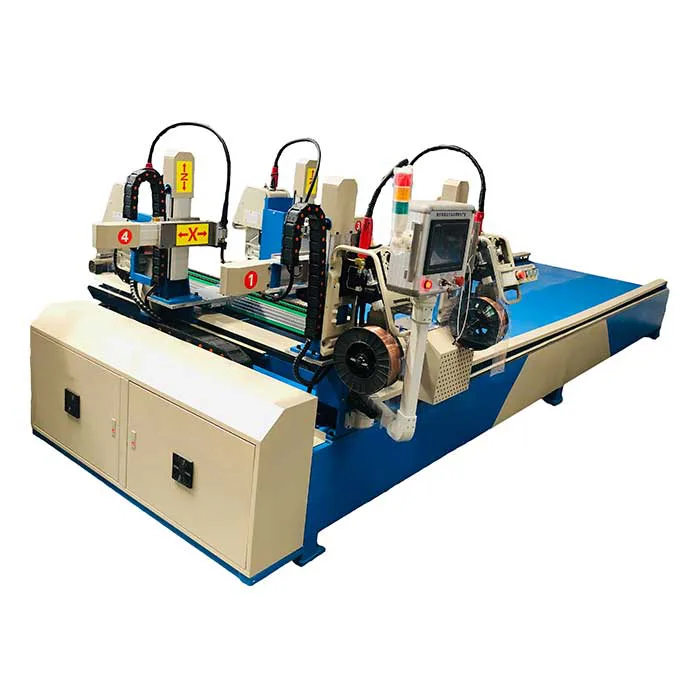

| Model | 4-CHT-1500X5000 |

| Steel Material | Cold roll steel |

| Angle Steel Thickness | 2,5-5mm |

| Minimum Angle Steel Size | 30X30mm |

| Maximum Angle Steel Size | 65X65mm |

| Minimum Welding Flange Size | 200X200mm |

| Maximum Welding Flange Size | 5000x1500mm |

| Welding Speed | 10m/min |

| Main Power | 10kw |

| Machine Dimension | 6200x2800x2350mm |

| Weight | 1900kg |