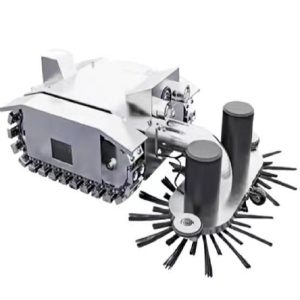

Double-head CNC round flange punching machine

Double-head CNC round flange punching machine

This machine is mainly used for automatic equal distribution punching of round flanges, and is widely used in the manufacture of round duct flanges, fan flanges, etc.

Function: Used for synchronous punching at both ends of circular flanges (metal/non-metal), suitable for mass production of ventilation duct flanges.

Features: Double-head design, high-precision positioning, automated operation, significantly improving production efficiency.

This machine is mainly used for automatic equal distribution punching of round flanges, and is widely used in the manufacture of round duct flanges, fan flanges, etc.

Function: Used for synchronous punching at both ends of circular flanges (metal/non-metal), suitable for mass production of ventilation duct flanges.

Features: Double-head design, high-precision positioning, automated operation, significantly improving production efficiency.

1. Double-head punching system

– Independent or linked punching heads at both ends, capable of simultaneously processing both sides of the flange, supporting multi-hole molds (bolt holes, positioning holes).

2. Positioning clamping mechanism

– Automatic centering clamps or hydraulic clamping ensure precise alignment between the flange center and punching positions.

3. Control System

– PLC or CNC system, pre-set parameters such as hole spacing and diameter, supports manual/automatic mode switching.

4. Feeding System

– Automatic feeding (optional), compatible with conveyor belts or robotic arms for continuous processing.

5. Safety Protection

– Emergency stop button, light curtain protection, compliant with industrial safety standards.

| Description | Unit | Parameters |

| Processing range | MM | 1.8-4mm |

| Material width | MM | 45-80 |

| Roll diameter | MM | 200-2000 |

| Feed rate | M/MIN | 15 |

| Dimensions | MM | 4300*800*1500 |

| Weight | KG | 3000 |