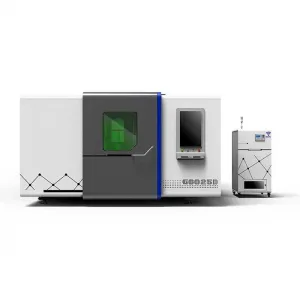

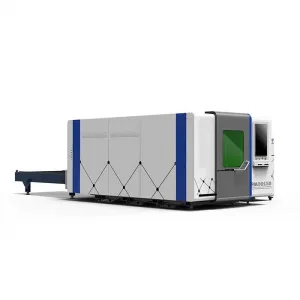

Steel coil laser cutting machine

Steel coil laser cutting machine

A steel coil laser cutting machine is a highly advanced, automated industrial system designed to process raw steel directly from a coiled state into precisely cut flat sheets or blanks. It integrates a coil decoiler, a leveling system, a feeding mechanism, and a high-power laser cutter into a single, continuous production line. This technology represents a significant leap in manufacturing efficiency for high-volume metal part production.

A steel coil laser cutting machine is a highly advanced, automated industrial system designed to process raw steel directly from a coiled state into precisely cut flat sheets or blanks. It integrates a coil decoiler, a leveling system, a feeding mechanism, and a high-power laser cutter into a single, continuous production line. This technology represents a significant leap in manufacturing efficiency for high-volume metal part production.

Laser Type: Fiber Laser (Industry standard for its efficiency with metals)

Laser Power: 3 kW – 20 kW+ (dependent on material type and thickness)

Coil Capacity: Up to 10+ tons (coil weight); 1500mm / 2000mm (coil width)

Material Thickness: 0.5mm – 12mm (Mild Steel, Stainless Steel, Aluminum)

Positioning Speed: Up to 200 m/min

Cutting Accuracy: ±0.1mm

Control System: PC-based CNC with dedicated software for nesting and path optimization

Coil Decoiler (Uncoiler): A heavy-duty mandrel that holds the large steel coil (often weighing several tons). It unwinds the coil in a controlled manner to feed the material into the line.

Material Leveler (Flattener): As the steel is uncoiled, it passes through a set of precision-leveling rollers. This crucial step removes the inherent curvature and internal stresses (coil set) from the coiled steel, ensuring it is perfectly flat before cutting.

Feeding System: A set of precision servo-driven pinch rollers that pull the flattened steel sheet through the production line at high speed and with extreme accuracy.

Flying Optic Laser Cutting Head: The heart of the machine. A high-power (typically ranging from 3kW to 12kW+) fiber laser source generates the cutting beam, which is directed to a cutting head that moves dynamically (on the X and Y axes) over the stationary material. A “flying” system allows for continuous cutting without stopping the material feed.

CNC Control System: The brain of the operation. It synchronizes the entire process—from uncoiling and feeding to laser cutting—based on digital CAD/CAM designs. It ensures precise cut shapes, nesting optimization, and minimal material waste.

Support Table & Skeleton Separator: After cutting, the finished parts (blanks) and the remaining skeleton (scrap framework) are cleanly separated and conveyed to collection areas, often via automated conveyors or stacking systems.