Why Packaging Machinery Matters Just as Much as Metal Fabrication Equipment

- By:Metmac

- 2025-05-04

- 1

I’ve spent years working with industrial machines—electrical press brakes, sheet metal bending machines, and bending brakes—and while these tools shape raw materials into precision parts, there’s another unsung hero in manufacturing: packaging machinery. It might not get the same attention as a high-tonnage metal bending machine, but without efficient packaging, even the most perfectly formed components would never reach customers intact.

The Silent Partner in Production Efficiency

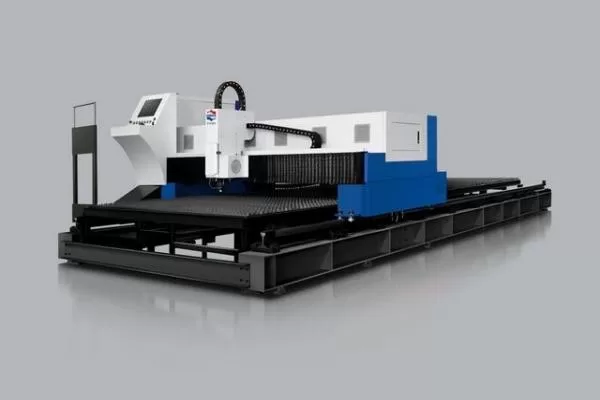

When you think about manufacturing, the first images that come to mind are likely sparks flying from a sheet metal cutting machine or the powerful hydraulics of a sheet bending machine. But what happens after production? That’s where packaging machinery steps in. Automated wrappers, sealers, and palletizers work tirelessly to ensure finished products—whether delicate brackets or heavy fabricated panels—are protected, labeled, and shipment-ready. Without this step, all the precision from your bending brakes means nothing if parts arrive damaged.

Cutting Costs, Not Corners

Manual packaging is slow, inconsistent, and expensive. In an industry where every second counts, automated packaging systems eliminate bottlenecks. Think about it: a sheet metal bending machine can produce hundreds of parts per hour—should packaging be the weak link? Machines that fold, seal, and box at high speeds ensure that production flow stays smooth from fabrication to freight. Plus, optimized material usage means less waste, which is just as important in packaging as it is in sheet metal cutting.

Protecting What You’ve Worked Hard to Create

A perfectly bent metal panel from an electrical press brake can be ruined by a single dent in transit. Proper packaging isn’t just about boxing things up—it’s about shock absorption, moisture resistance, and secure stacking. Automated packaging systems apply the right amount of cushioning and reinforcement, something human workers can’t always replicate with consistency.

Meeting the Demand for Speed and Precision

Today’s market doesn’t tolerate delays. If your metal bending machine can produce parts faster than ever, your packaging must keep up. Automated systems scale effortlessly, handling surges in orders without the need for overtime or temporary workers.

Final Thoughts

While sheet bending machines and bending brakes take center stage in fabrication, packaging machinery is the backbone of logistics. Investing in robust packaging solutions isn’t an afterthought—it’s a necessity for protecting your product’s value, reducing waste, and keeping customers satisfied. After all, what good is precision manufacturing if the final step lets you down?

From the shop floor to the shipping dock, every machine has its role. And in modern manufacturing, packaging deserves just as much attention as the tools that shape the metal itself.

-

Why Packaging Machinery Matters Just as Much as Metal Fabrication Equipment

2025/05/04 -

The Advantages of Using a Sheet Roll Forming Machine in Manufacturing

2024/09/14 -

How to Optimize Your Laser Sheet Cutting Machine for Maximum Performance

2024/09/12 -

How to Maximize Efficiency with Modern Sheet Metal Working Machines

2024/09/04

-

A Guide to the Latest Innovations in Sheet Metal Folding Machines

2024/11/29 -

Key Features to Consider When Investing in a Sheet Metal Folding Machine

2024/11/28 -

Enhancing Precision with Advanced Sheet Metal Folding Machines

2024/11/27 -

How to Choose the Right Sheet Metal Folding Machine for Your Workshop

2024/11/26