Precision and Power: The Evolution of Sheet Metal Machinery for Modern Manufacturing

- By:Metmac

- 2025-05-20

- 132

Precision metal fabrication depends heavily on the reliability and efficiency of advanced sheet metal machinery. From the automotive sector to HVAC, construction, and furniture production, the demand for flexible, high-performance metal forming tools is constantly increasing. Among these, the sheet bending machine and sheet metal cutting machine are foundational technologies that drive speed, accuracy, and repeatability in production lines.

A sheet bending machine plays a critical role in shaping flat metal sheets into desired profiles. Whether the end product requires straight bends, complex angles, or radius curves, modern press brakes and panel benders offer digitally controlled precision that reduces human error and material waste. CNC sheet bending equipment, often powered by electric or hybrid servo systems, ensures consistent output even with intricate designs. Manufacturers value these machines for their ability to handle diverse materials like stainless steel, aluminum, and galvanized sheet with ease.

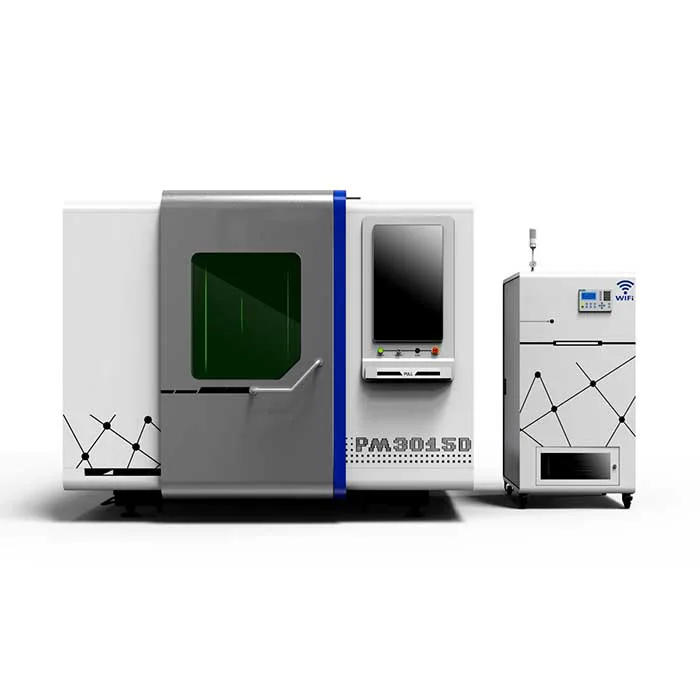

Complementing the bending process is the sheet metal cutting machine, designed to create clean, accurate cuts across a variety of sheet types and thicknesses. Equipment such as hydraulic shears, plasma cutters, and fiber laser cutting machines are commonly found in workshops looking to streamline their operations. Laser-based cutting systems, in particular, are gaining popularity for their ability to maintain tight tolerances while minimizing burrs and heat-affected zones.

The integration of both cutting and bending equipment into a cohesive sheet metal machinery line allows businesses to maximize workflow efficiency. Advanced automation and smart controls offer operators real-time feedback, reducing downtime and improving overall productivity. This is particularly important in high-mix, low-volume production environments where flexibility and quick changeovers are crucial.

Metmac offers a robust lineup of sheet metal solutions that cater to both small-scale workshops and large industrial operations. The brand’s machines are built with a focus on durability, precision engineering, and ease of operation. Their sheet bending machines come in various configurations, including electric and hydraulic models with CNC integration. Meanwhile, sheet metal cutting machines offered on their platform range from traditional guillotine shears to state-of-the-art fiber laser systems.

Choosing the right combination of sheet metal machinery is not just about technical specifications—it’s about aligning with a partner who understands your manufacturing challenges. From initial consultation to machine commissioning and after-sales support, long-term reliability is just as important as short-term performance gains.

For manufacturers looking to modernize their fabrication process or expand production capacity, investing in high-quality sheet bending and cutting machines is a step toward greater efficiency and competitiveness. Explore Metmac’s full product line and find a solution tailored to your business goals.

-

Iron Sheet Laser Cutting Machine: Unmatched Precision for Demanding Fabrication with METMAC

2026/01/06 -

Precision Metal Cutting Machine: The Engine of Modern Manufacturing, Powered by METMAC

2026/01/06 -

Sheet Metal CNC Laser Cutting Machine: Precision Redefined with METMAC Technology

2026/01/06 -

Sheet Metal Press Brake for Sale: Find Your Precision Bending Solution with METMAC

2026/01/06

-

Advanced Sheet Metal Rolling, Laser Cutting, and Folding Machines for Precision Fabrication

2025/10/31 -

High-Performance Sheet Metal Bending and Cutting Machines for Modern Fabrication

2025/10/31 -

High-Quality Sheet Metal Equipment for Sale: Efficient Solutions for Modern Manufacturing

2025/10/31 -

High-Performance Sheet Metal Equipment for Sale: Forming and Shearing Solutions for Modern Fabrication

2025/10/22

-

Latest Technological Advancements in Rectangular Duct Machines

2024/05/11 -

Integrating Automation with Rectangular Duct Machines for Enhanced Productivity

2024/05/11 -

Metal Shear Machines- Essential Tools for Precision Metal Cutting

2024/05/11 -

Understanding the Role and Function of Steel Strip Slitting Machines

2024/05/11

-

A Guide to the Latest Innovations in Sheet Metal Folding Machines

2024/11/29 -

Key Features to Consider When Investing in a Sheet Metal Folding Machine

2024/11/28 -

Enhancing Precision with Advanced Sheet Metal Folding Machines

2024/11/27 -

How to Choose the Right Sheet Metal Folding Machine for Your Workshop

2024/11/26