High-Performance Sheet Metal Bending and Cutting Machines for Modern Fabrication

- By:Metmac

- 2025-10-31

- 32

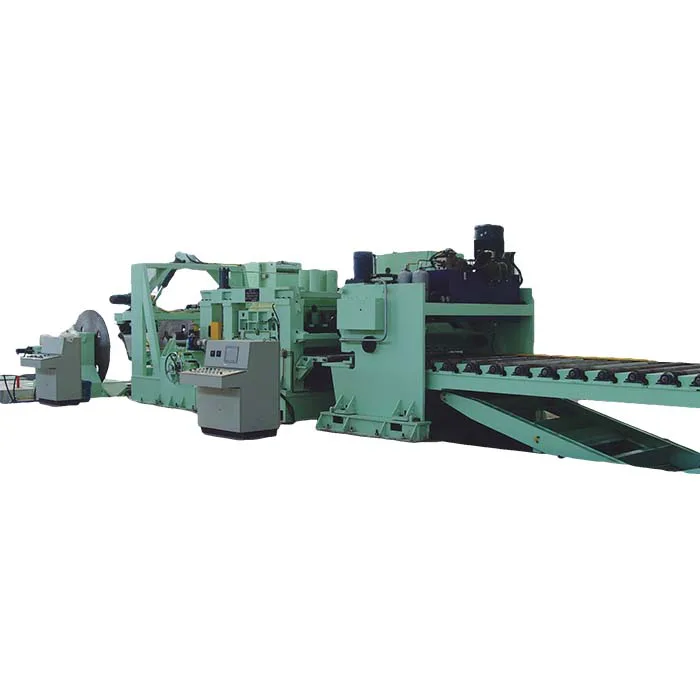

Efficient metal fabrication relies on precise and durable machinery. A sheet metal bending machine is an essential tool for shaping metal sheets into accurate angles and forms. By providing consistent bending performance, these machines ensure that products meet exact specifications, reduce material waste, and maintain high production efficiency. Industries ranging from automotive to construction benefit greatly from the precision and reliability offered by modern bending machines.

A sheet bending machine allows operators to perform complex bends with minimal effort. With adjustable settings and advanced control systems, these machines can handle various sheet thicknesses and materials, including steel, aluminum, and stainless steel. This versatility makes them suitable for both large-scale industrial applications and smaller workshop projects. Automated features in many models further improve productivity, reduce errors, and provide repeatable results across batches.

Alongside bending machines, a sheet metal cutting machine is critical for preparing materials before shaping and assembly. These machines provide clean, straight cuts, reducing the need for additional finishing work. Advanced sheet metal cutting machines offer programmable controls, high cutting speeds, and safety mechanisms, ensuring efficient and precise operations. By streamlining the cutting process, manufacturers can reduce production time, minimize scrap, and maintain consistent output quality.

When selecting sheet metal equipment, it is important to consider not only performance but also durability and ease of maintenance. High-quality sheet metal bending machines and sheet metal cutting machines offer long-term reliability, enabling manufacturers to achieve precision results while reducing downtime. Many modern machines integrate bending and cutting functions, creating a seamless workflow that enhances overall efficiency in metalworking operations.

For workshops and smaller production facilities, compact sheet bending and cutting machines provide flexibility without sacrificing performance. These machines maintain the essential capabilities of larger industrial models, such as accurate bends, programmable cutting, and material versatility. This allows manufacturers to execute both prototype development and small-batch production with the same level of precision and quality.

Investing in reliable sheet metal bending machines and sheet metal cutting machines enhances productivity, reduces material waste, and ensures consistent, high-quality results. By utilizing advanced metal fabrication equipment, manufacturers can meet the demands of modern production while maintaining operational efficiency. Whether for large-scale industrial applications or small workshop tasks, these machines provide the accuracy, durability, and flexibility required for successful metalworking.

With the right combination of bending and cutting machinery, manufacturers can streamline their fabrication processes, achieve precise dimensions, and produce durable, high-quality products. Modern sheet metal equipment delivers the performance needed to remain competitive and meet the growing demands of today’s manufacturing environment.

-

Iron Sheet Laser Cutting Machine: Unmatched Precision for Demanding Fabrication with METMAC

2026/01/06 -

Precision Metal Cutting Machine: The Engine of Modern Manufacturing, Powered by METMAC

2026/01/06 -

Sheet Metal CNC Laser Cutting Machine: Precision Redefined with METMAC Technology

2026/01/06 -

Sheet Metal Press Brake for Sale: Find Your Precision Bending Solution with METMAC

2026/01/06

-

Advanced Sheet Metal Rolling, Laser Cutting, and Folding Machines for Precision Fabrication

2025/10/31 -

High-Performance Sheet Metal Bending and Cutting Machines for Modern Fabrication

2025/10/31 -

High-Quality Sheet Metal Equipment for Sale: Efficient Solutions for Modern Manufacturing

2025/10/31 -

High-Performance Sheet Metal Equipment for Sale: Forming and Shearing Solutions for Modern Fabrication

2025/10/22

-

Latest Technological Advancements in Rectangular Duct Machines

2024/05/11 -

Integrating Automation with Rectangular Duct Machines for Enhanced Productivity

2024/05/11 -

Metal Shear Machines- Essential Tools for Precision Metal Cutting

2024/05/11 -

Understanding the Role and Function of Steel Strip Slitting Machines

2024/05/11

-

A Guide to the Latest Innovations in Sheet Metal Folding Machines

2024/11/29 -

Key Features to Consider When Investing in a Sheet Metal Folding Machine

2024/11/28 -

Enhancing Precision with Advanced Sheet Metal Folding Machines

2024/11/27 -

How to Choose the Right Sheet Metal Folding Machine for Your Workshop

2024/11/26