Customization Capabilities- Designing Unique Products with Sheet Roll Forming Machines

- By:Metmac

- 2024-05-29

- 16

In today’s competitive manufacturing landscape, businesses seek innovative ways to differentiate their products and cater to increasingly diverse customer needs. Sheet roll forming machines offer exceptional customization capabilities, empowering manufacturers to design and produce unique products that meet specific requirements.

Precision and Accuracy

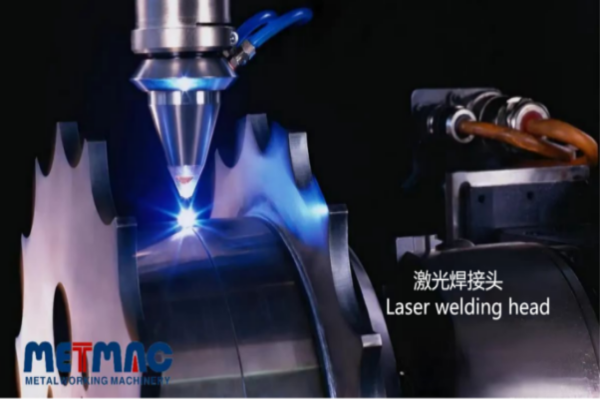

Sheet roll forming machines utilize a series of rollers to shape and bend sheet metal with high precision. This precision allows for the creation of complex shapes and intricate designs, ensuring that products conform to precise specifications and meet stringent quality standards. The consistent bending force applied by the rollers ensures accuracy throughout the forming process, reducing the risk of errors and minimizing waste.

Flexibility and Versatility

Sheet roll forming machines offer immense flexibility, accommodating various materials, thicknesses, and widths. This versatility enables manufacturers to produce a wide range of products, from architectural components to automotive parts. The ability to tailor the forming process to specific materials and requirements allows for the creation of highly customized products that cater to unique applications.

Complex Geometries

Roll forming technology empowers designers to create complex geometries that would be challenging or impossible to produce using traditional manufacturing methods. By manipulating the shape and angle of the rollers, manufacturers can achieve a wide range of bends, curves, and profiles. This capability opens up new possibilities for product design, enabling the creation of innovative and aesthetically pleasing components.

Integration and Automation

Sheet roll forming machines can be integrated into automated production lines, further enhancing customization and efficiency. Automated feeding systems ensure consistent material flow, while advanced software allows for precise control over the forming process. By leveraging automation, manufacturers can streamline production, reduce human error, and achieve higher levels of customization while maintaining quality.

Custom Tooling

The use of custom tooling is integral to the customization capabilities of sheet roll forming machines. By designing and fabricating custom tooling specific to the desired product, manufacturers can precisely shape the material and achieve unique profiles. This enables the production of highly specialized components that meet exact specifications and cater to niche applications.

In conclusion, Customization Capabilities: Designing Unique Products with Sheet Roll Forming Machines underscores the transformative power of this technology in today’s manufacturing environment. By embracing the precision, flexibility, and automation offered by sheet roll forming machines, businesses can push the boundaries of product design, create highly customized components, and meet the ever-evolving demands of their customers.

-

Integrating Automation with Rectangular Duct Machines for Enhanced Productivity

2024/05/11 -

Metal Shear Machines- Essential Tools for Precision Metal Cutting

2024/05/11 -

Understanding the Role and Function of Steel Strip Slitting Machines

2024/05/11 -

Maintenance Tips for Longevity of HVAC Duct Machines

2024/05/11