Top Features to Look for in a Round Duct Machine

- By:Metmac

- 2024-05-20

- 49

Unveiling the Top Features to Look for in a Round Duct Machine

In the intricate world of HVAC systems, the humble round duct machine plays a pivotal role, shaping the seamless flow of conditioned air. As you embark on the quest for the perfect round duct machine, it is imperative to scrutinize its key features to ensure optimal performance and efficiency.

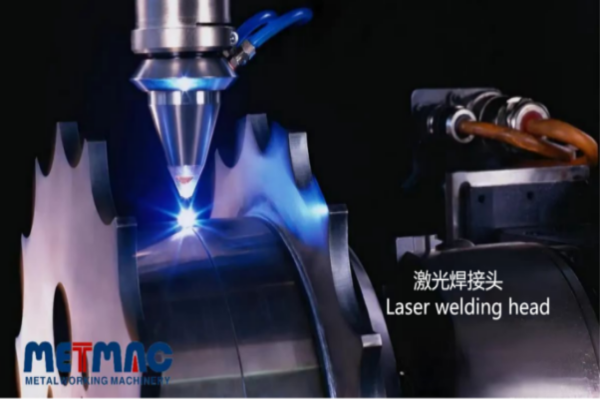

1. Cut-to-Length Precision:

The accuracy of your duct cutting is paramount. Look for machines that employ innovative laser or digital measurement systems to precisely cut ducts to the desired length, eliminating costly material wastage and ensuring seamless assembly.

2. Seamless Roll Forming:

The ability to form round ducts with uniform thickness and airtight seals is crucial. Machines equipped with precision rollers and advanced forming techniques minimize distortion, ensuring structural integrity and efficient airflow.

3. Efficient Flanging:

The flanges at duct ends provide secure connections and prevent air leaks. Seek machines with advanced flanging mechanisms that create consistent and durable flanges, enhancing airtightness and system performance.

4. Operator-Friendly Controls:

A user-friendly interface simplifies operation and reduces setup time. Intuitive touchscreens, digital displays, and automated controls allow for precise adjustments and seamless integration with other HVAC components.

5. Durability and Maintenance:

The endurance of your round duct machine is essential. Opt for machines constructed from sturdy materials like heavy-duty steel, equipped with robust components that withstand the rigors of daily use. Adequate maintenance features, such as easy-to-access parts and lubrication points, ensure longevity.

6. Safety Compliance:

Safety is non-negotiable. Machines compliant with industry regulations, such as OSHA standards, provide essential safeguards for operators. Look for features like emergency stop buttons, pinch point guards, and grounding systems to protect against potential hazards.

7. Energy Efficiency:

In today’s environmentally conscious world, energy efficiency is paramount. Choose machines that incorporate energy-saving technologies, such as variable speed drives or optimized hydraulic systems, to minimize power consumption and reduce operating costs.

8. Technological Advancements:

Stay abreast of industry advancements by seeking machines that integrate cutting-edge technologies like IoT connectivity, AI-assisted diagnostics, or remote monitoring capabilities. These features enhance convenience, increase productivity, and improve system performance.

By carefully considering these top features, you can navigate the vast array of round duct machines and make an informed choice that meets the specific demands of your HVAC projects. Remember, the perfect machine will empower you to create high-quality ducts, optimize airflow, and elevate the comfort and efficiency of any building.

-

Understanding the Role and Function of Steel Strip Slitting Machines

2024/05/11 -

Maintenance Tips for Longevity of HVAC Duct Machines

2024/05/11 -

Innovations in Steel Strip Slitting Machine Design and Technology

2024/05/11 -

Improving Accuracy in Metal Fabrication with Laser Metal Shear Machines

2024/05/11