Understanding Metal Sheet Cutting Machine Price: Why METMAC Offers Unmatched Value

- By:Metmac

- 2025-12-16

- 26

Understanding Metal Sheet Cutting Machine Price: Why METMAC Offers Unmatched Value

Understanding Metal Sheet Cutting Machine Price

When searching for a “metal sheet cutting machine price,” you’re met with a vast range of figures, from surprisingly low to investment-level high. This disparity often leads to a critical question: what truly determines the cost, and more importantly, the value? For businesses seeking not just a machine, but a partner in productivity and precision, the brand behind the technology makes all the difference. This is where METMAC positions itself—not as the cheapest option, but as the definitive solution for unparalleled long-term return on investment.

The initial purchase price of a metal sheet cutting machine is just one line in a much larger spreadsheet of operational costs. Factors influencing this price include the cutting technology (fiber laser, plasma, waterjet), power output, working bed size, automation features, and software sophistication. However, focusing solely on the upfront cost overlooks the more significant financial impacts: cutting speed, precision, energy consumption, maintenance downtime, and part longevity.

METMAC engineers its machines with a holistic philosophy centered on Total Cost of Ownership (TCO). A lower-priced machine might save capital today but can cost exponentially more tomorrow in wasted materials, slow production speeds, frequent repairs, and early replacement. METMAC’s pricing reflects an investment in eliminating these hidden expenses.

Precision That Reduces Waste, Power That Enhances Speed

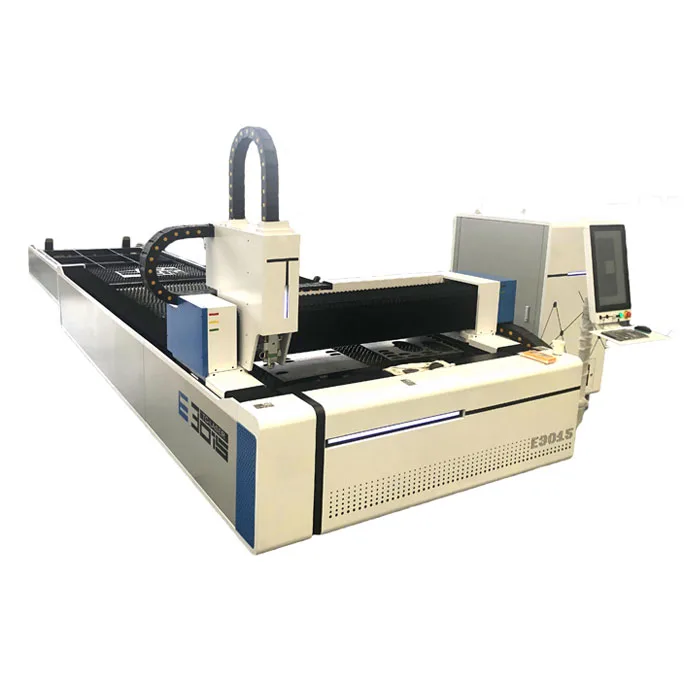

At the core of METMAC’s value proposition is exceptional precision. Our advanced fiber laser cutting machines deliver clean, dross-free cuts with tolerances that minimize secondary finishing. In metal fabrication, material is a primary cost. Inaccurate cutting leads to scrap, directly eroding profit margins. METMAC’s robust construction, high-quality components like German-made laser sources and precision guides, and intuitive CNC controls ensure that every cut is optimal, dramatically reducing material waste. When calculating “metal sheet cutting machine price,” the savings from a 2% reduction in scrap over a year can often outweigh the difference in initial investment.

Furthermore, METMAC machines are built for speed and reliability. High acceleration rates, efficient piercing cycles, and reliable components allow for continuous operation. This translates to more parts produced per shift, maximizing your revenue potential from the asset. The machine’s price is amortized over a vastly higher output, effectively lowering the cost per cut.

Durability and Uptime: The Invisible Line Items

A machine sitting idle is a liability. METMAC’s reputation for rugged durability is a direct contributor to its value. We use heavy-duty frames and industry-leading components to withstand the demands of 24/7 industrial environments. This results in fewer breakdowns and significantly lower maintenance costs. Our pricing includes the peace of mind that comes from exceptional build quality, ensuring your production line keeps moving.

Smart Features and Software: Value Beyond the Hardware

The modern metal sheet cutting machine is a computer-connected hub. METMAC provides proprietary and integrated software that streamlines the workflow from CAD design to finished part. Features like intelligent nesting optimize material usage, while user-friendly interfaces reduce programming time and operator error. This software suite, included with our systems, enhances efficiency and is a critical part of the value equation not always found in base-level machine prices.

Transparency and Partnership: The METMAC Promise

When you request a METMAC quote for a “metal sheet cutting machine price,” you receive a detailed, transparent proposal. We don’t believe in hidden costs. Our experts work with you to understand your specific needs—material types, thicknesses, desired throughput—and recommend the optimal model. We factor in installation, training, and initial support to ensure a smooth transition.

Our price reflects a comprehensive partnership. It includes expert training for your team, comprehensive after-sales support, and readily available spare parts. This reduces your risk and ensures the machine performs at its peak for years, protecting your investment.

Conclusion: Calculating True Value

The quest for a “metal sheet cutting machine price” should ultimately be a quest for value. It’s an analysis of performance, reliability, and support over a 5 to 10-year horizon.

METMAC builds machines that command a competitive price based on superior engineering and a commitment to lowering your total operational costs. The investment in a METMAC machine is an investment in higher productivity, minimal waste, legendary durability, and a partnership dedicated to your growth.

Instead of asking for the lowest price, ask for the lowest cost per perfect part over the next decade. That’s the calculation where METMAC consistently proves its worth.

Ready to see the METMAC difference? Contact our engineering team today for a personalized consultation and a detailed quote tailored to your production goals. Let’s build the future of metal fabrication, together.

-

Iron Sheet Laser Cutting Machine: Unmatched Precision for Demanding Fabrication with METMAC

2026/01/06 -

Precision Metal Cutting Machine: The Engine of Modern Manufacturing, Powered by METMAC

2026/01/06 -

Sheet Metal CNC Laser Cutting Machine: Precision Redefined with METMAC Technology

2026/01/06 -

Sheet Metal Press Brake for Sale: Find Your Precision Bending Solution with METMAC

2026/01/06

-

Advanced Sheet Metal Rolling, Laser Cutting, and Folding Machines for Precision Fabrication

2025/10/31 -

High-Performance Sheet Metal Bending and Cutting Machines for Modern Fabrication

2025/10/31 -

High-Quality Sheet Metal Equipment for Sale: Efficient Solutions for Modern Manufacturing

2025/10/31 -

High-Performance Sheet Metal Equipment for Sale: Forming and Shearing Solutions for Modern Fabrication

2025/10/22

-

Latest Technological Advancements in Rectangular Duct Machines

2024/05/11 -

Integrating Automation with Rectangular Duct Machines for Enhanced Productivity

2024/05/11 -

Metal Shear Machines- Essential Tools for Precision Metal Cutting

2024/05/11 -

Understanding the Role and Function of Steel Strip Slitting Machines

2024/05/11

-

A Guide to the Latest Innovations in Sheet Metal Folding Machines

2024/11/29 -

Key Features to Consider When Investing in a Sheet Metal Folding Machine

2024/11/28 -

Enhancing Precision with Advanced Sheet Metal Folding Machines

2024/11/27 -

How to Choose the Right Sheet Metal Folding Machine for Your Workshop

2024/11/26