Sheet Metal Laser Cutting Machine: How METMAC is Redefining Precision and Power

- By:Metmac

- 2025-11-18

- 82

Sheet Metal Laser Cutting Machine: How METMAC is Redefining Precision and Power

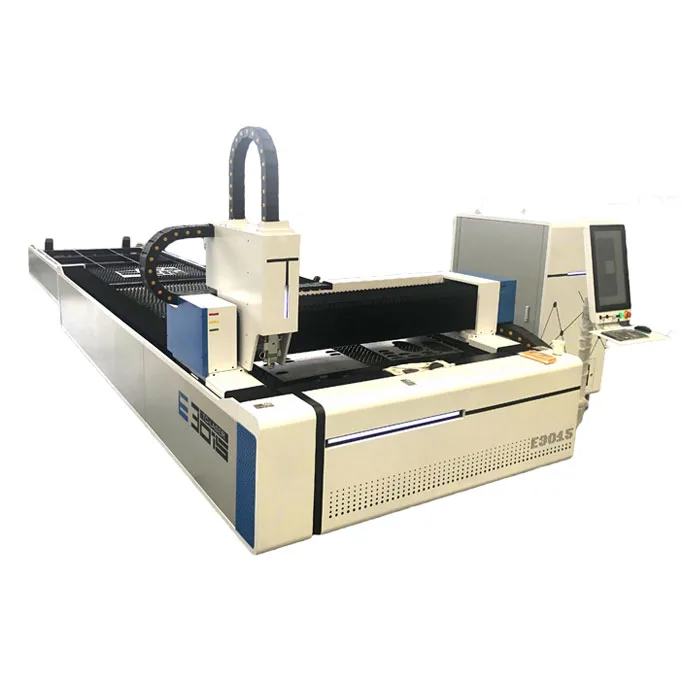

Sheet Metal Laser Cutting Machine

In the world of modern manufacturing, precision isn’t just a advantage—it’s the absolute foundation of quality, efficiency, and innovation. At the heart of this precision-driven era lies a transformative technology: the sheet metal laser cutting machine. For businesses seeking not just a tool, but a strategic partner in production, the choice of laser cutting technology is pivotal. This is where METMAC emerges as a leader, engineering laser cutting systems that blend raw power with unparalleled accuracy to empower factories worldwide.

The core principle of laser cutting is elegant in its simplicity, yet profoundly complex in its execution. A high-powered laser beam is focused through a sophisticated lens and nozzle onto a sheet of metal—be it steel, aluminum, brass, or copper. This concentrated energy heats the material to a point where it melts, vaporizes, or is blown away by a high-pressure assist gas, leaving an exceptionally clean and precise cut. The superiority of this method over traditional mechanical cutting lies in the non-contact nature of the process. There is no tool wear, no risk of contamination, and minimal physical stress on the material, resulting in flawless edges and intricate details that were once thought impossible.

The METMAC Difference: Engineering Beyond the Beam

While the fundamental technology is shared across the industry, the performance, durability, and ROI of a sheet metal laser cutting machine are determined by the engineering philosophy behind it. METMAC builds its machines with a clear vision: to create assets that are relentlessly reliable, intuitively operable, and capable of handling the most demanding production schedules.

- Uncompromising Structural Integrity: A laser cutter is only as stable as its frame. METMAC constructs its machines from high-grade, thermally-stable materials, employing robust welding techniques and advanced stress-relieving processes. This results in a machine that maintains its geometric alignment and stability year after year, even under continuous operation. This foundational rigidity is non-negotiable for achieving micron-level precision consistently, regardless of the cutting speed or material thickness.

- Advanced Fiber Laser Source: METMAC integrates state-of-the-art fiber laser sources into its systems. Fiber laser technology represents a significant leap forward in energy efficiency and cutting performance. Compared to older CO2 laser types, METMAC’s fiber lasers consume significantly less power, have a longer operational lifespan, and excel at cutting reflective metals like aluminum and copper with breathtaking speed and quality. This means lower operational costs and a faster time-to-part for our clients.

- Intelligent Software and Automation: A powerful machine is nothing without intelligent command. METMAC’s proprietary and compatible software suites transform complex cutting tasks into simple, streamlined operations. Features like automatic nesting optimize material usage, drastically reducing waste and saving costs. Furthermore, METMAC specializes in integrating automated loading and unloading systems, turning a standalone machine into a continuous, lights-out production cell. This capability to run unattended for hours dramatically increases overall equipment effectiveness (OEE) and maximizes our clients’ production throughput.

Applications That Shape Industries

The versatility of a METMAC sheet metal laser cutting machine unlocks potential across a vast spectrum of industries. Its ability to handle diverse materials and thicknesses with equal finesse makes it an indispensable tool.

- Automotive and Aerospace: From robust chassis components and intricate brackets to lightweight aircraft interior parts, METMAC machines deliver the stringent tolerances and repeatability required by these high-stakes sectors.

- Electronics and Enclosures: Creating precise housings, ventilation grills, and mounting plates for sensitive electronic equipment demands a burr-free, stress-free cut. METMAC’s technology ensures every part is clean and ready for assembly.

- Architecture and Construction: From decorative metal panels and custom facades to structural elements, architects and designers rely on METMAC to bring their most ambitious visions to life with perfect accuracy.

- Industrial Machinery: The production of heavy machinery depends on durable, accurately cut parts. METMAC machines handle thick plates with power and consistency, ensuring the reliability of the final industrial product.

Beyond the Machine: The METMAC Partnership

Choosing a METMAC sheet metal laser cutting machine is the beginning of a partnership. We understand that downtime is the enemy of productivity. Our global support network is engineered for rapid response, with expert technicians and a comprehensive inventory of spare parts. From initial installation and comprehensive operator training to ongoing maintenance and technical support, the METMAC team is committed to ensuring your investment delivers maximum value throughout its entire lifecycle.

Our engineers work closely with clients to understand their unique production challenges and goals. This collaborative approach allows us to recommend not just a standard model, but a tailored solution—whether it’s a specific bed size, laser power configuration, or a fully automated material handling system.

The Future, Cut with Precision

As manufacturing evolves towards greater connectivity and smarter factories (Industry 4.0), METMAC is at the forefront. Our machines are designed with IoT capabilities, allowing for real-time monitoring of machine performance, predictive maintenance alerts, and seamless data integration into your factory management systems. This forward-thinking design protects your investment and ensures your manufacturing capabilities remain competitive in a rapidly changing landscape.

In conclusion, a sheet metal laser cutting machine is more than a capital expense; it is the engine of your fabrication capabilities. In a market filled with options, METMAC stands apart by fusing robust German-inspired engineering with cutting-edge laser technology and an unwavering commitment to customer success. We don’t just sell machines; we deliver precision, power, and productivity, empowering businesses to cut cleaner, faster, and smarter.

Discover the METMAC difference. Visit us at www.metmac.com to learn how our laser cutting solutions can transform your production floor and become the cornerstone of your manufacturing quality.

-

2027 Essential Guide to Choosing the Perfect Bold**Wood and Fabric Bed Frame** for Your Bedroom

2026/03/05 -

2027 Latest Trends in Wood and Fabric Bed Frames for Modern Bedrooms: Comprehensive Buyer’s Guide & Top Styles Breakdown

2026/03/05 -

Wood and Fabric Bed Frames: Pros, Cons, and 2027 Maintenance Tips You Need to Know

2026/03/05 -

Iron Sheet Laser Cutting Machine: Unmatched Precision for Demanding Fabrication with METMAC

2026/01/06

-

Advanced Sheet Metal Rolling, Laser Cutting, and Folding Machines for Precision Fabrication

2025/10/31 -

High-Performance Sheet Metal Bending and Cutting Machines for Modern Fabrication

2025/10/31 -

High-Quality Sheet Metal Equipment for Sale: Efficient Solutions for Modern Manufacturing

2025/10/31 -

High-Performance Sheet Metal Equipment for Sale: Forming and Shearing Solutions for Modern Fabrication

2025/10/22

-

Understanding the Role and Function of Steel Strip Slitting Machines

2024/05/11 -

Maintenance Tips for Longevity of HVAC Duct Machines

2024/05/11 -

Innovations in Steel Strip Slitting Machine Design and Technology

2024/05/11 -

Improving Accuracy in Metal Fabrication with Laser Metal Shear Machines

2024/05/11

-

A Guide to the Latest Innovations in Sheet Metal Folding Machines

2024/11/29 -

Key Features to Consider When Investing in a Sheet Metal Folding Machine

2024/11/28 -

Enhancing Precision with Advanced Sheet Metal Folding Machines

2024/11/27 -

How to Choose the Right Sheet Metal Folding Machine for Your Workshop

2024/11/26