Iron Sheet Cutting Machine Price: What to Expect and Why METMAC Delivers True Value

- By:Metmac

- 2025-12-30

- 100

Iron Sheet Cutting Machine Price: What to Expect and Why METMAC Delivers True Value

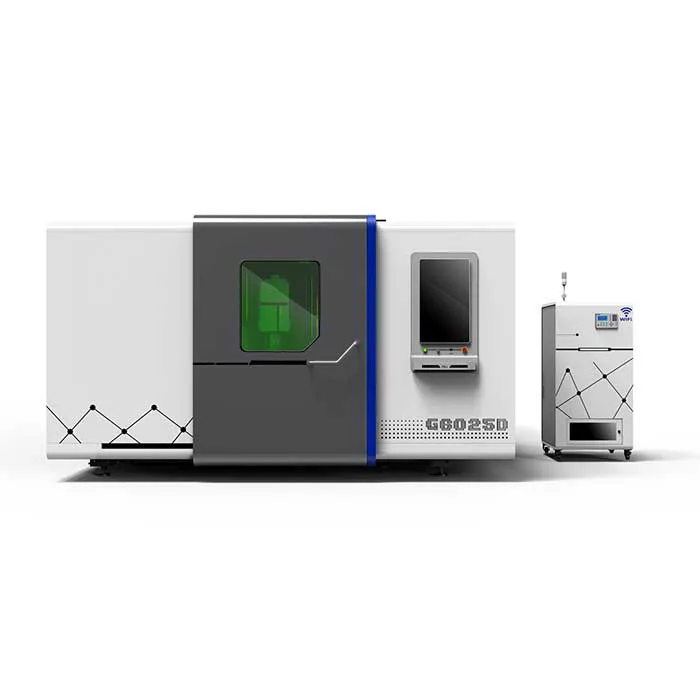

Iron Sheet Cutting Machine Price

When it comes to investing in industrial machinery, the question of “iron sheet cutting machine price” is often the starting point for manufacturers and fabricators worldwide. While cost is a crucial factor, focusing solely on the initial price tag can be misleading. True value lies in performance, precision, durability, and the total cost of ownership. This is where METMAC, a brand synonymous with innovation and reliability in metal fabrication, redefines the equation. Understanding the pricing landscape for these machines requires a look at the technology, the features offered, and the long-term benefits a brand like METMAC provides.

Understanding the Price Spectrum for Iron Sheet Cutting Machines

The price of an iron sheet cutting machine is not a single figure but a range, influenced by several key factors. At the entry-level, you may find simpler mechanical or basic hydraulic shears. These machines cater to light-duty or occasional use and come with a lower initial cost. However, for consistent, high-volume, and precision cutting of various iron sheets (including mild steel, galvanized steel, and more), manufacturers need to look toward more advanced solutions.

The core of the price differentiation lies in the technology. Conventional hydraulic shears with numerical control represent a significant step up, offering better accuracy and repeatability. The premium segment is dominated by fully CNC (Computer Numerical Control) machines and those incorporating advanced laser or plasma cutting technology. A CNC iron sheet cutting machine price reflects its transformative capabilities: automated back gauges, servo-driven systems, sophisticated blade gap adjustment, and software integration for minimal waste and maximum throughput. These features drastically reduce labor costs, material waste, and error rates, paying for themselves over time in a busy workshop.

Beyond the Invoice: The METMAC Advantage

This is the context in which METMAC shines. When you evaluate an iron sheet cutting machine, you are investing in your factory’s productivity for the next decade or more. METMAC engineers its machines with this long-term partnership in mind. Here’s what sets METMAC apart and contributes to the superior value behind its pricing:

- Uncompromising Precision and Rigidity: Every METMAC shear is built with a robust, vibration-resistant frame. This ensures clean, burr-minimized cuts cycle after cycle, year after year. Accuracy is not a luxury; it’s a standard. This precision eliminates costly rework and ensures your downstream processes run smoothly.

- Advanced Control and Ease of Use: METMAC machines often feature intuitive CNC interfaces that simplify complex operations. Programming multiple cuts, adjusting parameters, and storing job data become effortless, reducing training time and operator dependency. This technological edge directly translates to faster job turnaround and flexibility.

- Durability that Lowers Lifetime Cost: The initial iron sheet cutting machine price must be amortized over the machine’s lifespan. METMAC uses high-grade components, precision-ground blades, and durable hydraulic systems designed for continuous operation. This superior build quality minimizes downtime, reduces maintenance costs, and extends the machine’s operational life far beyond average, offering a far better return on investment.

- Focus on Safety and Productivity: METMAC integrates advanced safety features as standard—from optical light curtains to robust guarding. A safe machine is a productive machine, protecting your most valuable asset: your team. Furthermore, features like fast blade approach speeds and rapid back gauge positioning are engineered to maximize cutting cycles per hour.

- Application-Specific Engineering: Not all iron sheets are the same, and neither are cutting requirements. METMAC offers a range of machines capable of handling different thicknesses, lengths, and types of material. Whether you are in automotive component manufacturing, construction material supply, or heavy equipment fabrication, METMAC provides a solution optimized for your specific output needs, ensuring you pay for capability you will actually use.

Making an Informed Investment Decision

Therefore, when researching “iron sheet cutting machine price,” we encourage you to frame the question differently: “What is the total value and productivity gain of this investment?” The goal is to find a machine that boosts your competitive edge.

A METMAC machine represents an investment in predictable performance. It’s the confidence of knowing your machine will handle today’s order and the unforeseen rush job tomorrow. It’s the savings from reduced scrap material and the ability to take on more complex, higher-margin projects thanks to superior accuracy. It’s the peace of mind that comes with reliable, safe operation and the support of a brand committed to the metal fabrication industry.

The most competitive price is not always the lowest upfront cost. It is the price that delivers the lowest cost per perfectly cut sheet over the lifetime of the equipment. This is the calculation where METMAC consistently proves its worth.

To explore the specific models, capabilities, and how a METMAC iron sheet cutting machine can transform your fabrication output, we invite you to visit our official website at www.metmac.com. Discover the engineering, the specifications, and the METMAC difference for yourself. Let’s discuss how we can build the optimal solution for your productivity goals.

-

2027 Essential Guide to Choosing the Perfect Bold**Wood and Fabric Bed Frame** for Your Bedroom

2026/03/05 -

2027 Latest Trends in Wood and Fabric Bed Frames for Modern Bedrooms: Comprehensive Buyer’s Guide & Top Styles Breakdown

2026/03/05 -

Wood and Fabric Bed Frames: Pros, Cons, and 2027 Maintenance Tips You Need to Know

2026/03/05 -

Iron Sheet Laser Cutting Machine: Unmatched Precision for Demanding Fabrication with METMAC

2026/01/06

-

Advanced Sheet Metal Rolling, Laser Cutting, and Folding Machines for Precision Fabrication

2025/10/31 -

High-Performance Sheet Metal Bending and Cutting Machines for Modern Fabrication

2025/10/31 -

High-Quality Sheet Metal Equipment for Sale: Efficient Solutions for Modern Manufacturing

2025/10/31 -

High-Performance Sheet Metal Equipment for Sale: Forming and Shearing Solutions for Modern Fabrication

2025/10/22

-

A Guide to the Latest Innovations in Sheet Metal Folding Machines

2024/11/29 -

Key Features to Consider When Investing in a Sheet Metal Folding Machine

2024/11/28 -

Enhancing Precision with Advanced Sheet Metal Folding Machines

2024/11/27 -

How to Choose the Right Sheet Metal Folding Machine for Your Workshop

2024/11/26