Efficient Sheet Metal Cutting Solutions for Every Application

- By:Metmac

- 2025-06-19

- 108

Metal fabrication requires reliable, precise, and cost-effective machinery to meet production goals and maintain product quality. Whether you’re managing a high-volume manufacturing facility or operating a small workshop, selecting the right equipment—such as sheet metal laser cutting machines for sale or mechanical shearing machines—can significantly improve workflow and output.

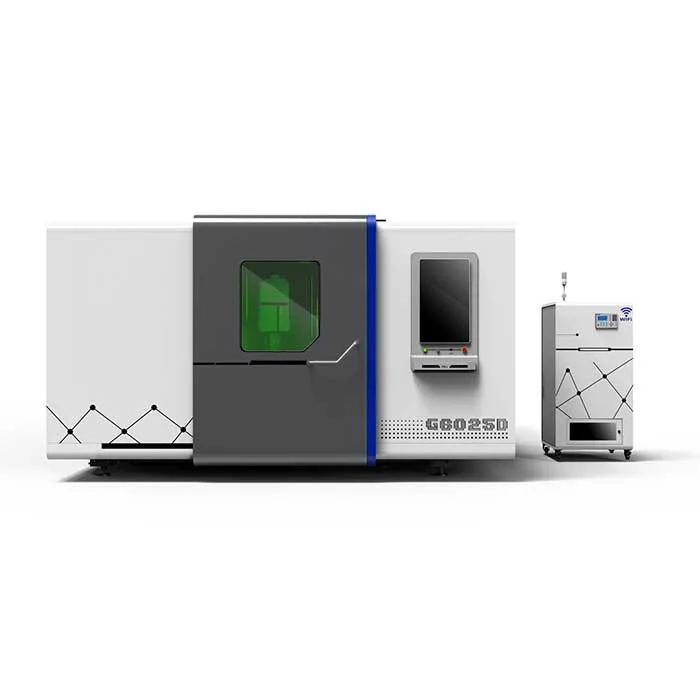

Laser cutting remains one of the most efficient methods for producing clean, accurate cuts in thin to medium-gauge metal. For businesses seeking high-speed, automated operations, sheet metal laser cutting machines for sale offer an ideal solution. These machines utilize CNC control and fiber laser sources to deliver high-quality results with minimal post-processing. Their ability to handle complex designs and fine details makes them suitable for industries ranging from electronics to architectural metalwork.

Metmac provides a variety of CNC laser machines engineered for sheet metal applications. Built with durable frames, high-speed drives, and intuitive interfaces, these machines are designed for consistent performance in demanding industrial settings. Their compatibility with software and nesting programs ensures material optimization and reduced waste.

However, not every job requires the advanced features of a laser system. For straightforward cutting needs, a shear metal cutting machine can offer a practical and budget-friendly alternative. Shearing is particularly effective for straight-line cuts on iron, stainless steel, or aluminum sheets. The simplicity of operation, low maintenance requirements, and long blade life make shearing machines an essential tool in fabrication shops.

When comparing options, many businesses evaluate not only capabilities but also the iron sheet cutting machine price to stay within budget without compromising quality. Metmac offers competitively priced models that suit different scales of production—from manual guillotine shears to motorized systems with programmable backgauges. These machines provide efficient and repeatable cuts while requiring minimal training for operators.

Another advantage of shearing equipment is its versatility. With the right blade and clearance settings, operators can process a wide range of materials and thicknesses. For repetitive tasks or bulk cutting, mechanical shears offer exceptional throughput and operational simplicity.

Whether you’re looking to automate intricate designs with a CNC laser or seeking a dependable shear for heavy-duty tasks, Metmac delivers a comprehensive range of solutions. Their machines are designed for long-term performance and backed by technical support to ensure smooth integration into your production line.

Ultimately, investing in the right sheet metal laser cutting machines for sale, understanding the iron sheet cutting machine price, and choosing a robust shear metal cutting machine can enhance your manufacturing efficiency and reduce overall costs. With the right equipment in place, your operations can stay agile, productive, and competitive in a rapidly evolving metalworking industry.

-

Iron Sheet Laser Cutting Machine: Unmatched Precision for Demanding Fabrication with METMAC

2026/01/06 -

Precision Metal Cutting Machine: The Engine of Modern Manufacturing, Powered by METMAC

2026/01/06 -

Sheet Metal CNC Laser Cutting Machine: Precision Redefined with METMAC Technology

2026/01/06 -

Sheet Metal Press Brake for Sale: Find Your Precision Bending Solution with METMAC

2026/01/06

-

Advanced Sheet Metal Rolling, Laser Cutting, and Folding Machines for Precision Fabrication

2025/10/31 -

High-Performance Sheet Metal Bending and Cutting Machines for Modern Fabrication

2025/10/31 -

High-Quality Sheet Metal Equipment for Sale: Efficient Solutions for Modern Manufacturing

2025/10/31 -

High-Performance Sheet Metal Equipment for Sale: Forming and Shearing Solutions for Modern Fabrication

2025/10/22

-

A Guide to the Latest Innovations in Sheet Metal Folding Machines

2024/11/29 -

Key Features to Consider When Investing in a Sheet Metal Folding Machine

2024/11/28 -

Enhancing Precision with Advanced Sheet Metal Folding Machines

2024/11/27 -

How to Choose the Right Sheet Metal Folding Machine for Your Workshop

2024/11/26