Advanced Sheet Metal Cutting Solutions with CNC and Plasma Technology

- By:Metmac

- 2025-06-19

- 186

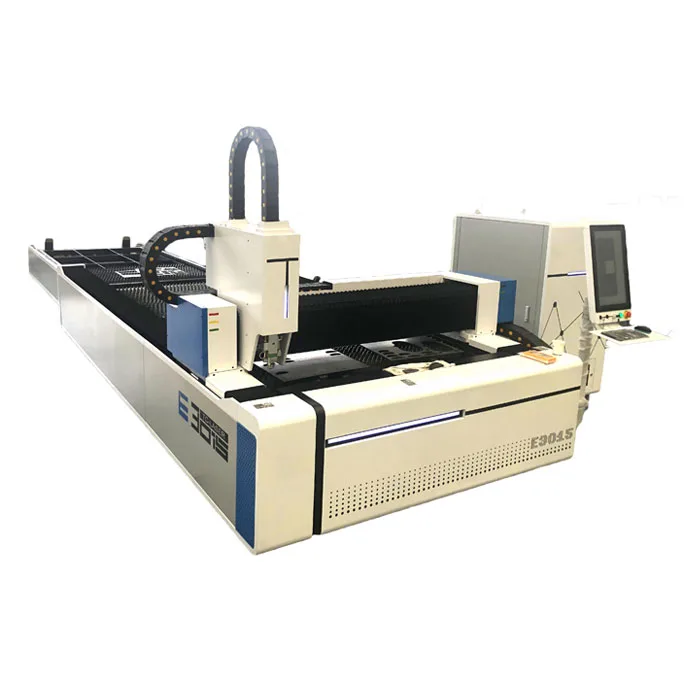

Precision and speed are critical in metal fabrication. Whether you’re manufacturing parts for the automotive industry, building HVAC systems, or producing custom metalwork, choosing the right cutting equipment is essential. A CNC laser cutting machine for sheet metal offers unmatched accuracy, minimal material waste, and high-speed processing, making it a cornerstone for modern sheet metal fabrication.

Laser cutting uses a focused beam of light to melt, burn, or vaporize material, resulting in clean and accurate cuts. This non-contact process reduces mechanical stress and deformation, especially important when working with thin-gauge or intricate sheet metal designs. With CNC control, the machine can follow precise digital patterns, ensuring repeatability and consistency even in complex geometries.

Metmac’s line of sheet metal laser cutting machines is designed for high-volume operations without sacrificing edge quality. These machines are equipped with advanced CNC controllers, fiber laser sources, and automated table systems, allowing for continuous cutting cycles and reduced setup time. Whether processing stainless steel, carbon steel, or aluminum, users benefit from tight tolerances and minimal finishing work.

For workshops or operations that prioritize affordability or work with thicker materials, a plasma sheet metal cutting machine may be the preferred solution. Plasma cutting uses a high-velocity jet of ionized gas to melt through conductive metals, making it a cost-effective option for medium to heavy-gauge steel. While it may not match the fine precision of laser systems, plasma cutting offers faster cutting speeds and higher throughput on thicker sheets.

One of the key factors in long-term success is working with trusted sheet metal laser cutting machine manufacturers who offer more than just machinery. Reliable technical support, spare parts availability, and integration with existing fabrication lines are essential. Metmac not only delivers cutting-edge technology but also provides full-cycle service—from consultation to after-sales support.

Automation is another growing trend in the cutting industry. Combining a CNC laser cutting machine sheet metal setup with auto-loading systems and digital job management software can dramatically improve productivity. This is especially valuable for manufacturers handling large orders with tight deadlines.

Choosing between laser and plasma cutting depends on your material type, thickness range, cut quality requirements, and budget. Laser cutting is ideal for tight tolerances and minimal kerf, while plasma excels in faster, lower-cost cutting of thicker plates. Metmac’s comprehensive portfolio ensures you can find a machine tailored to your specific needs.

In conclusion, modern sheet metal processing demands efficiency, accuracy, and scalability. Whether you’re seeking the precision of fiber lasers or the rugged performance of plasma systems, working with experienced sheet metal laser cutting machine manufacturers like Metmac ensures you stay competitive in an evolving market.

-

Iron Sheet Laser Cutting Machine: Unmatched Precision for Demanding Fabrication with METMAC

2026/01/06 -

Precision Metal Cutting Machine: The Engine of Modern Manufacturing, Powered by METMAC

2026/01/06 -

Sheet Metal CNC Laser Cutting Machine: Precision Redefined with METMAC Technology

2026/01/06 -

Sheet Metal Press Brake for Sale: Find Your Precision Bending Solution with METMAC

2026/01/06

-

Advanced Sheet Metal Rolling, Laser Cutting, and Folding Machines for Precision Fabrication

2025/10/31 -

High-Performance Sheet Metal Bending and Cutting Machines for Modern Fabrication

2025/10/31 -

High-Quality Sheet Metal Equipment for Sale: Efficient Solutions for Modern Manufacturing

2025/10/31 -

High-Performance Sheet Metal Equipment for Sale: Forming and Shearing Solutions for Modern Fabrication

2025/10/22

-

Understanding the Role and Function of Steel Strip Slitting Machines

2024/05/11 -

Maintenance Tips for Longevity of HVAC Duct Machines

2024/05/11 -

Innovations in Steel Strip Slitting Machine Design and Technology

2024/05/11 -

Improving Accuracy in Metal Fabrication with Laser Metal Shear Machines

2024/05/11

-

A Guide to the Latest Innovations in Sheet Metal Folding Machines

2024/11/29 -

Key Features to Consider When Investing in a Sheet Metal Folding Machine

2024/11/28 -

Enhancing Precision with Advanced Sheet Metal Folding Machines

2024/11/27 -

How to Choose the Right Sheet Metal Folding Machine for Your Workshop

2024/11/26