Five axis machining center EMU

Five axis machining center EMU

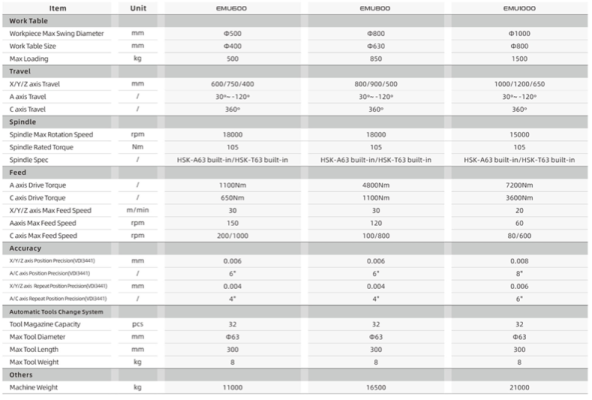

Adopt Integrated Box-ln-Box Crane Structure Design, Ensure Casting Structure’s High Rigidty、High Precision and High Stability

The Design Adopts Finite Element Analysis and Thermal Forming Analysis, Greatly Improved the Static and Dynamic Characteristics of the Machine Tool, Ensure Machine Tool’s Integral Rigidity. Stability and Machining Precision.

Integrated Box-In-Box Crane Structure, EMU800’s Casting Weight is 12 Tons, Whole Machine’s weight is 16.5 Tons, Lightweight Design Of Moving Parts, 3 axis Verticality are Contrled within弘

+ 3 axis All Adopt Japan NSK Ball Screw and Germany Rexroth Precison Linear Way, With Heidenhain High Precision Optical Scale, Precision is High, Stability is Good;

+ A axis (double drive)、 C axis Both Adopt DD Direct Drive Rotary Table, With土0.1P Frequency Conversion Spindle Water Cooler, Coolant Performance is Good. Particular Bearings and Brake Structure With Heidenhain High Precision Encoders, Rotational Torque is Big, Carrying Capacity is Strong. Precision is High, Stability is Good.

Adopt 190mm Diameter Spindle, Front 4pcs Back 2pcs Total 6pcs Bearings, S1 Torque can Reach 105Nm, With +0.1PFrequency Conversion Spindle Water Cooler, When do Low Speed Heavy Duty Cutting and High Speed Finish Machining, Both Have Very Good Performance;,

+ Adopt Siemens or Heidenhain Control System, With Big Torque Motors and Driver, Performance is Much Better Machine Standard Laser Tool Setter Instrument and Workpiece Probe, Not Only Ensured Tool Length and Tool Diameter’s Measure Precision, But AlIso Can do Self-check When Doing Machining.

Adopt Integrated Box-ln-Box Crane Structure Design, Ensure Casting Structure’s High Rigidty、High Precision and High Stability

The Design Adopts Finite Element Analysis and Thermal Forming Analysis, Greatly Improved the Static and Dynamic Characteristics of the Machine Tool, Ensure Machine Tool’s Integral Rigidity. Stability and Machining Precision.

Integrated Box-In-Box Crane Structure, EMU800’s Casting Weight is 12 Tons, Whole Machine’s weight is 16.5 Tons, Lightweight Design Of Moving Parts, 3 axis Verticality are Contrled within弘

+ 3 axis All Adopt Japan NSK Ball Screw and Germany Rexroth Precison Linear Way, With Heidenhain High Precision Optical Scale, Precision is High, Stability is Good;

+ A axis (double drive)、 C axis Both Adopt DD Direct Drive Rotary Table, With土0.1P Frequency Conversion Spindle Water Cooler, Coolant Performance is Good. Particular Bearings and Brake Structure With Heidenhain High Precision Encoders, Rotational Torque is Big, Carrying Capacity is Strong. Precision is High, Stability is Good.

Adopt 190mm Diameter Spindle, Front 4pcs Back 2pcs Total 6pcs Bearings, S1 Torque can Reach 105Nm, With +0.1PFrequency Conversion Spindle Water Cooler, When do Low Speed Heavy Duty Cutting and High Speed Finish Machining, Both Have Very Good Performance;,

+ Adopt Siemens or Heidenhain Control System, With Big Torque Motors and Driver, Performance is Much Better Machine Standard Laser Tool Setter Instrument and Workpiece Probe, Not Only Ensured Tool Length and Tool Diameter’s Measure Precision, But AlIso Can do Self-check When Doing Machining.

Main Structure Features

X axis 3pcs Linear Way(Germany Rexroth)

Y axis 4pcs Linear Way(Germany Rexroth)

Integrated Box-In-Box Structure,Z axis 4pcs Linear Way(Germany Rexroth)

Front and Back Double Cross-beams Design,The Force is More Even, Ensured Z axis Verticality Well 3 axis Verticality all are controlled within 3μ, Spatial Accuracy is Much Higher

DD Rotary Table is Fixed on Base, Load-bearing Capacity is More Stronger, Vibration is More Smaller

The Contact Surface Between Base and Columns is Very Big,Rigidity is Very Good,EMU630’s Weight Reach 16.5 Tons