Sheet Roll Forming Machine: The METMAC Advantage in Precision Engineering

- By:Metmac

- 2025-12-09

- 21

Sheet Roll Forming Machine: The METMAC Advantage in Precision Engineering

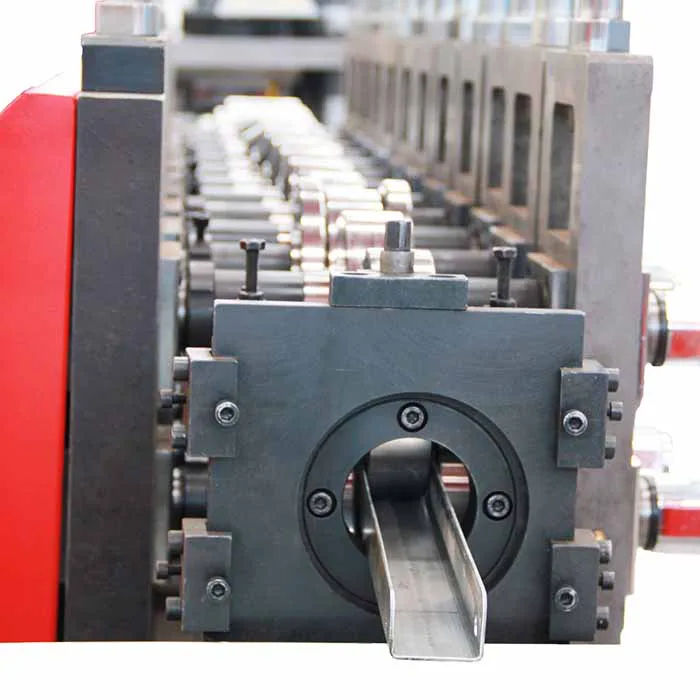

In the world of industrial manufacturing, efficiency, precision, and reliability are not just goals—they are imperatives. For businesses that depend on the consistent, high-volume production of metal profiles, the choice of machinery defines their operational ceiling. At the heart of this production lies the sheet roll forming machine, a sophisticated piece of engineering that transforms coiled metal into consistent, complex cross-sections. For industry leaders seeking not just a machine, but a strategic partner in production, the METMAC brand stands as a symbol of innovation, durability, and unparalleled performance.

Understanding the Precision of Roll Forming

A sheet roll forming machine is a continuous bending operation where a long strip of sheet metal is passed through consecutive sets of rolls, each performing an incremental part of the bend until the desired cross-sectional profile is achieved. Unlike other metal shaping methods, roll forming is renowned for its ability to produce consistent, high-strength parts with excellent surface finish at remarkable speeds. The applications are vast, spanning construction (roofing, wall panels, structural components), automotive industries, appliance manufacturing, and countless custom fabrication needs.

The true challenge, however, lies in achieving this consistency over millions of cycles. Tolerance deviations, material springback, wear on tooling, and speed limitations can become significant bottlenecks. This is where the core engineering philosophy of a manufacturer becomes critical.

The METMAC Engineering Philosophy: Built for the Demanding

METMAC approaches every sheet roll forming machine not as a commodity, but as a integrated system. Our philosophy is rooted in the understanding that our customers’ productivity depends on every component functioning in perfect harmony, day after day, under strenuous conditions.

- Robust Construction for Unwavering Stability: The foundation of any precise machine is its frame. METMAC machines are built with heavy-duty, high-grade steel frames and bases, engineered to absorb vibrations and maintain critical alignment. This inherent stability is non-negotiable; it ensures that every roll station operates in perfect relation to the next, guaranteeing profile consistency from the first foot of production to the ten-thousandth.

- Advanced Drive and Control Systems: Precision is commanded from the control panel. METMAC integrates state-of-the-art servo-driven technology and programmable logic controllers (PLCs) into our roll forming systems. This allows for exceptional control over speed, synchronization, and positioning. Quick-change setups, repeatable precision for different profiles, and user-friendly interfaces minimize downtime and reduce the potential for operator error, translating directly into higher output and lower operational costs.

- Superior Tooling and Material Compatibility: The heart of the forming process is the tooling. METMAC designs and manufactures precision tooling using superior materials and advanced heat treatment processes. Our engineering team meticulously calculates the forming steps to ensure smooth material flow, minimizing stress and wear on both the tooling and the metal sheet. Whether processing mild steel, aluminum, galvanized materials, or pre-painted coils, a METMAC machine is calibrated to handle the specific characteristics of the material, preserving coating integrity and delivering a flawless finish.

- Integrated Flexibility and Customization: We recognize that no two production lines are identical. METMAC specializes in providing tailored solutions. Our sheet roll forming machines can be seamlessly integrated with pre-punching systems, cut-off presses (flying or stationary), embossing units, and automated stacking equipment. This flexibility allows us to deliver a complete, turnkey production line that transforms raw coil into finished, packaged parts with minimal manual intervention.

Why METMAC Makes the Difference

Choosing a METMAC sheet roll forming machine is an investment in long-term competitive advantage. The benefits are tangible:

- Enhanced Productivity: High operational speeds coupled with rapid changeover capabilities maximize your production uptime.

- Uncompromised Quality: Consistent, repeatable precision ensures every part meets exact specifications, drastically reducing waste and rework.

- Reduced Total Cost of Ownership: Durable construction and accessible service points mean lower maintenance costs and longer machine life. Our efficient design also contributes to energy savings over time.

- Expert Partnership: METMAC is more than a supplier. Our team of engineers provides comprehensive support, from initial design consultation and factory acceptance testing to installation supervision, operator training, and readily available spare parts support.

A Commitment to Shaping Industry Standards

For decades, METMAC has been at the forefront of roll forming technology. Our machines are at work globally, supporting manufacturers in building infrastructure, creating vehicles, and constructing appliances that people rely on every day. We are driven by a passion for engineering excellence and a deep commitment to our clients’ success.

In the precise, high-stakes world of metal forming, the machinery you choose is the bedrock of your quality and output. The sheet roll forming machine from METMAC represents the synthesis of robust engineering, intelligent control, and adaptable design. It is engineered not just to shape metal, but to shape the future of manufacturing businesses, providing the reliability and precision needed to excel in a demanding market.

Discover the METMAC difference. Explore how our engineered solutions can elevate your production line, enhance your product quality, and strengthen your bottom line. Visit us at www.metmac.com to learn more about our capabilities and to begin a conversation about your specific roll forming challenges. Let’s build the future of manufacturing, together.

-

Iron Sheet Laser Cutting Machine: Unmatched Precision for Demanding Fabrication with METMAC

2026/01/06 -

Precision Metal Cutting Machine: The Engine of Modern Manufacturing, Powered by METMAC

2026/01/06 -

Sheet Metal CNC Laser Cutting Machine: Precision Redefined with METMAC Technology

2026/01/06 -

Sheet Metal Press Brake for Sale: Find Your Precision Bending Solution with METMAC

2026/01/06

-

Advanced Sheet Metal Rolling, Laser Cutting, and Folding Machines for Precision Fabrication

2025/10/31 -

High-Performance Sheet Metal Bending and Cutting Machines for Modern Fabrication

2025/10/31 -

High-Quality Sheet Metal Equipment for Sale: Efficient Solutions for Modern Manufacturing

2025/10/31 -

High-Performance Sheet Metal Equipment for Sale: Forming and Shearing Solutions for Modern Fabrication

2025/10/22

-

A Guide to the Latest Innovations in Sheet Metal Folding Machines

2024/11/29 -

Key Features to Consider When Investing in a Sheet Metal Folding Machine

2024/11/28 -

Enhancing Precision with Advanced Sheet Metal Folding Machines

2024/11/27 -

How to Choose the Right Sheet Metal Folding Machine for Your Workshop

2024/11/26