Sheet Metal Rolling Machine for Sale: Finding Precision and Durability with METMAC

- By:Metmac

- 2025-12-09

- 25

Sheet Metal Rolling Machine for Sale: Finding Precision and Durability with METMAC

Sheet Metal Rolling Machine for Sale

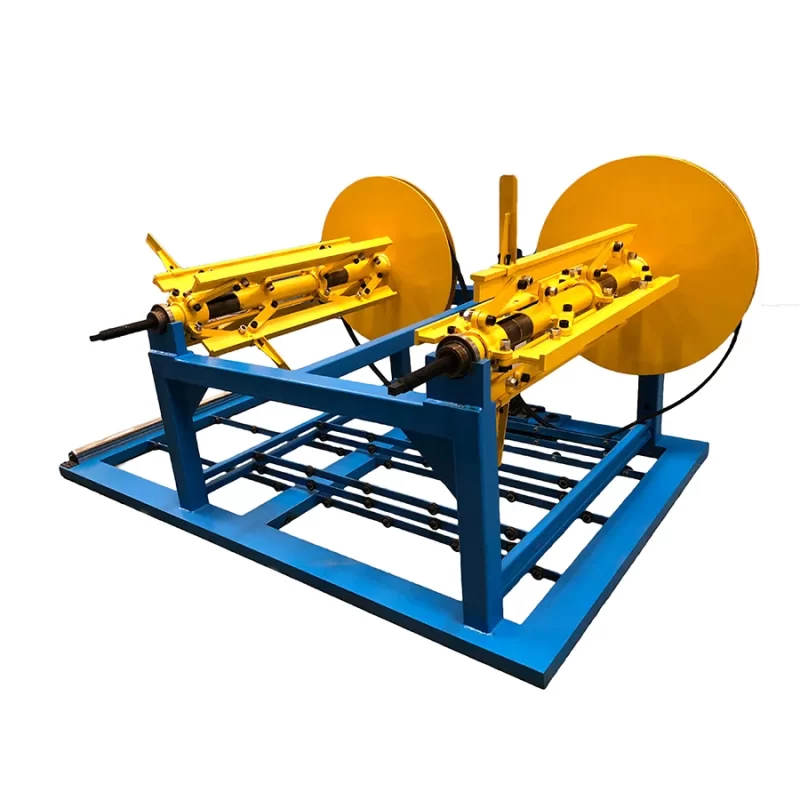

In the dynamic world of metal fabrication, the ability to accurately and efficiently form curves, cylinders, and cones from sheet metal is a fundamental capability. A sheet metal rolling machine, often referred to as a plate roller or initial pinch roller, is the essential piece of equipment that makes this possible. Whether creating structural components for aerospace, cylindrical housings for industrial equipment, or architectural features, the precision of the rolling process directly impacts the quality and functionality of the final product. For fabricators, shipyards, and manufacturers seeking a reliable sheet metal rolling machine for sale, the decision extends beyond mere purchase—it is an investment in long-term capability, accuracy, and productivity. In this competitive landscape, METMAC stands as a premier provider, offering not just machinery, but engineered solutions built for performance and endurance.

Understanding the Role of Precision Rolling

A sheet metal rolling machine operates by feeding a flat sheet of metal between three or more rollers, which apply controlled pressure to gradually bend the material into a consistent radius or cylindrical shape. The process demands exceptional control over pressure, alignment, and roll positioning to avoid defects like flattening, edge curling, or inconsistent curvature. Key considerations when evaluating a sheet metal rolling machine for sale include its capacity (metal thickness and width), the type of rolling (initial pinch, pyramid, or variable geometry), the level of control (manual, NC, or CNC), and its overall rigidity.

The challenge for buyers is to find a machine that offers both the necessary power for demanding materials and the finesse required for precise, repeatable results. It must be versatile enough to handle various project sizes yet robust enough to maintain accuracy over years of service. This is where the distinction between a generic machine and a METMAC-engineered system becomes profoundly clear.

The METMAC Advantage: Engineered for Real-World Fabrication

When exploring the market for a sheet metal rolling machine for sale, METMAC represents a commitment to superior engineering. Our machines are designed from the ground up to meet the rigorous demands of professional fabrication environments, where downtime is costly and precision is expected.

- Uncompromising Structural Rigidity: The foundation of any accurate rolling machine is its frame and roller strength. METMAC machines are constructed with heavy-duty, stress-relieved steel frames and precision-machined rollers. This robust design ensures minimal deflection under full load, which is critical for producing consistent curves across the entire width of the sheet, especially when working with high-tensile materials or at maximum capacity. Our commitment to rigidity guarantees that the machine’s performance remains stable, year after year.

- Advanced Control for Repeatable Results: Modern fabrication requires digital precision. METMAC integrates user-friendly yet sophisticated control systems into our sheet metal rolling machines. From simple digital readouts to full CNC controls, our systems provide exact command over roll positioning, synchronization, and pressure. Features like automatic crowning compensation, programmable memory for repeat jobs, and intuitive interfaces empower operators to set up jobs quickly and execute complex rolls with confidence, drastically reducing setup time and material trial-and-error.

- Superior Drive Systems and Tooling: The smooth application of power is vital. METMAC utilizes high-efficiency hydraulic or electromechanical drive systems designed for smooth, powerful, and reliable operation. Coupled with our specially engineered rollers—often fabricated from high-grade alloy steels and finished to exacting tolerances—the system ensures optimal material flow. This combination minimizes slippage and marring, preserving the surface quality of painted, coated, or sensitive materials while delivering the forming power needed for the job.

- Versatility and Customized Configurations: We understand that no two shops are identical. METMAC offers a range of sheet metal rolling machines, from standard initial pinch models to more specialized variable geometry or four-roll machines for enhanced productivity. Furthermore, we provide options for side supports, cone rolling attachments, and material handling systems. Our engineering team can work with you to tailor a machine configuration that optimally fits your specific workflow, material mix, and production goals.

Why Choose a METMAC Sheet Metal Rolling Machine?

Selecting a METMAC machine translates into direct benefits for your operational efficiency and business reputation:

- Precision You Can Depend On: Achieve tight tolerances and consistent radii, ensuring parts fit together correctly the first time, reducing rework and assembly challenges.

- Enhanced Productivity: Faster setup, powerful rolling capabilities, and reliable performance mean you can complete more jobs on schedule, increasing workshop throughput.

- Expanded Material and Job Scope: With a robust METMAC machine, your shop can confidently accept a wider variety of projects, handling thicker plates, wider sheets, and more challenging alloys, thus opening new revenue streams.

- Durability That Lowers Lifetime Cost: Investing in a well-built machine reduces long-term operating costs. METMAC’s focus on quality components and accessible service points means greater uptime, fewer repairs, and a much longer operational lifespan, delivering a superior return on investment.

Your Partner in Metal Forming Excellence

METMAC is more than a manufacturer; we are a long-term partner in your fabrication success. Our process begins with a detailed consultation to understand your needs and recommend the most suitable sheet metal rolling machine. We support this with comprehensive after-sales service, including installation supervision, thorough operator training, and readily available technical support and spare parts.

In an industry where the quality of your tools defines the quality of your output, settling for less is not an option. A METMAC sheet metal rolling machine for sale represents the convergence of power, precision, and durability. It is an investment that empowers your team to tackle complex forming tasks with assurance, enhance your shop’s capabilities, and build a stronger, more competitive business.

If you are evaluating your options for a sheet metal rolling machine for sale, look to a brand built on engineering integrity. Discover the METMAC difference by exploring our detailed specifications and machine portfolios at www.metmac.com. Contact our technical sales team today to discuss your application requirements and learn how a METMAC rolling machine can become the cornerstone of your forming department.

-

Iron Sheet Laser Cutting Machine: Unmatched Precision for Demanding Fabrication with METMAC

2026/01/06 -

Precision Metal Cutting Machine: The Engine of Modern Manufacturing, Powered by METMAC

2026/01/06 -

Sheet Metal CNC Laser Cutting Machine: Precision Redefined with METMAC Technology

2026/01/06 -

Sheet Metal Press Brake for Sale: Find Your Precision Bending Solution with METMAC

2026/01/06

-

Advanced Sheet Metal Rolling, Laser Cutting, and Folding Machines for Precision Fabrication

2025/10/31 -

High-Performance Sheet Metal Bending and Cutting Machines for Modern Fabrication

2025/10/31 -

High-Quality Sheet Metal Equipment for Sale: Efficient Solutions for Modern Manufacturing

2025/10/31 -

High-Performance Sheet Metal Equipment for Sale: Forming and Shearing Solutions for Modern Fabrication

2025/10/22

-

A Guide to the Latest Innovations in Sheet Metal Folding Machines

2024/11/29 -

Key Features to Consider When Investing in a Sheet Metal Folding Machine

2024/11/28 -

Enhancing Precision with Advanced Sheet Metal Folding Machines

2024/11/27 -

How to Choose the Right Sheet Metal Folding Machine for Your Workshop

2024/11/26