Sheet Metal Processing Machines: Revolutionizing Fabrication with METMAC Innovation

- By:Metmac

- 2026-01-06

- 97

Sheet Metal Processing Machines: Revolutionizing Fabrication with METMAC Innovation

Sheet Metal Processing Machines

In the dynamic world of industrial manufacturing, precision, efficiency, and reliability are not mere advantages—they are the fundamental pillars of success. At the forefront of this demanding landscape, sheet metal processing machines stand as the critical backbone, transforming raw materials into intricate components for industries ranging from aerospace and automotive to construction and consumer electronics. For fabricators seeking not just to compete but to lead, the choice of machinery is a strategic decision that impacts every facet of operation. This is where METMAC establishes its distinguished legacy, engineering a comprehensive range of sheet metal processing machines that embody technological excellence and unwavering durability.

The challenges in modern sheet metal fabrication are multifaceted. Shorter lead times, increasingly complex designs, stringent quality standards, and the imperative to minimize material waste demand equipment that is both powerfully robust and intelligently adaptable. Traditional machines often force a compromise between speed and precision, or between initial cost and long-term operational economy. METMAC’s philosophy dismantles this compromise. We design and build our machines with a deep understanding of the shop floor, creating solutions that empower our clients to achieve more—more output, more accuracy, and more profitability.

Our core portfolio encompasses the essential pillars of sheet metal fabrication. METMAC Press Brakes are engineered for exceptional bending accuracy and repeatability. Featuring advanced CNC controls, intuitive programming interfaces, and robust construction, they ensure that every bend, from simple angles to complex geometries, is executed with flawless consistency. Whether equipped with hydraulic or electric drive systems, METMAC brakes are synonymous with control, allowing operators to handle everything from delicate, thin-gauge sheets to heavy, thick-plate applications with confidence.

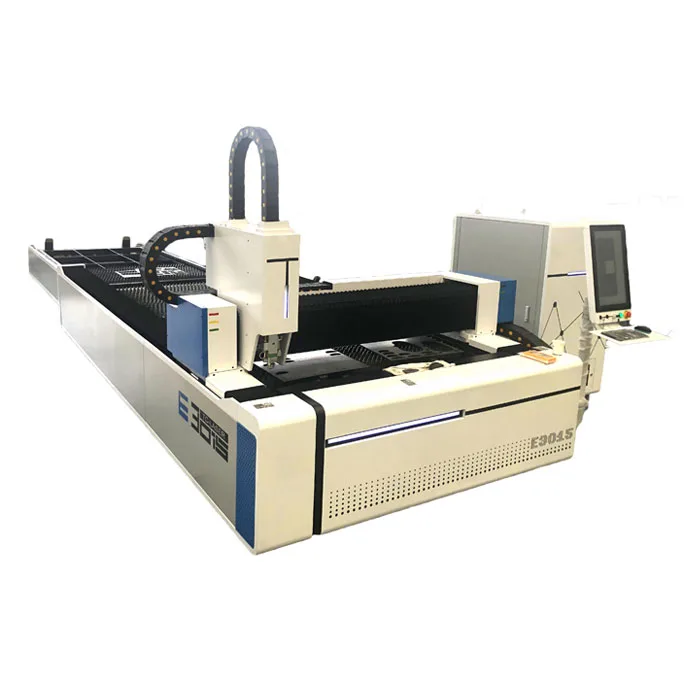

Complementing our bending technology, METMAC Laser Cutting Machines represent the pinnacle of thermal cutting precision. By integrating high-performance fiber laser sources with state-of-the-art motion systems and cutting heads, we deliver machines that produce clean, dross-free edges at remarkable speeds. The precision of a METMAC laser minimizes the need for secondary finishing, drastically reduces kerf width to optimize material utilization, and unlocks the potential to produce intricate contours and fine details that are impossible with mechanical methods. Our focus on energy efficiency and low maintenance requirements ensures that this precision is also cost-effective over the machine’s entire lifecycle.

For high-volume punching and forming tasks, METMAC Turret Punch Presses offer unparalleled productivity. Designed for relentless performance, these machines combine high-speed punching with flexible tooling systems. The ability to handle a vast array of tools within a single setup drastically reduces changeover times, making them ideal for batch production and just-in-time manufacturing. With features like automatic sheet loading and sophisticated nesting software, METMAC punch presses maximize throughput while maintaining the ruggedness needed for 24/7 operation.

Beyond these core categories, METMAC’s innovation extends to a suite of supporting equipment, including Precision Shearing Machines for clean, distortion-free blanking and Automated Handling Systems that create seamless, integrated production cells. We recognize that true efficiency is achieved not through standalone islands of automation, but through connected, smart workflows. Our machines are built with connectivity in mind, ready to interface with factory-wide MES (Manufacturing Execution Systems) and leverage data analytics for predictive maintenance and process optimization.

What truly differentiates METMAC, however, is not just the machinery itself, but the engineering ethos behind it. Every METMAC machine is a product of rigorous research, premium-grade components, and meticulous assembly. We subject our equipment to exhaustive testing, ensuring they meet the most demanding standards for performance and safety before they reach our clients. This commitment to quality translates directly into tangible benefits for fabricators: reduced downtime, lower long-term operating costs, and a superior return on investment.

Moreover, METMAC stands as a true partner. Our global network of technical support and service professionals provides unparalleled after-sales care. From comprehensive operator training and application support to readily available spare parts and expert maintenance, we ensure that our clients’ productivity is never interrupted. This end-to-end support ecosystem guarantees that a METMAC machine continues to perform at its peak for years, even decades.

In conclusion, as the specifications for sheet metal parts grow tighter and market pressures intensify, the machinery you choose becomes the most critical determinant of your capability and competitiveness. METMAC provides more than just equipment; we provide a foundation for manufacturing excellence. Our sheet metal processing machines are engineered to turn challenges into opportunities—delivering the precision to realize the most ambitious designs, the speed to meet the most urgent deadlines, and the durability to build a lasting legacy of quality.

For fabricators who define their success by the caliber of their output, the choice is clear. It is a choice for innovation engineered to last. It is a choice for METMAC. Discover the future of fabrication at www.metmac.com.

-

2027 Essential Guide to Choosing the Perfect Bold**Wood and Fabric Bed Frame** for Your Bedroom

2026/03/05 -

2027 Latest Trends in Wood and Fabric Bed Frames for Modern Bedrooms: Comprehensive Buyer’s Guide & Top Styles Breakdown

2026/03/05 -

Wood and Fabric Bed Frames: Pros, Cons, and 2027 Maintenance Tips You Need to Know

2026/03/05 -

Iron Sheet Laser Cutting Machine: Unmatched Precision for Demanding Fabrication with METMAC

2026/01/06

-

Advanced Sheet Metal Rolling, Laser Cutting, and Folding Machines for Precision Fabrication

2025/10/31 -

High-Performance Sheet Metal Bending and Cutting Machines for Modern Fabrication

2025/10/31 -

High-Quality Sheet Metal Equipment for Sale: Efficient Solutions for Modern Manufacturing

2025/10/31 -

High-Performance Sheet Metal Equipment for Sale: Forming and Shearing Solutions for Modern Fabrication

2025/10/22

-

Latest Technological Advancements in Rectangular Duct Machines

2024/05/11 -

Integrating Automation with Rectangular Duct Machines for Enhanced Productivity

2024/05/11 -

Metal Shear Machines- Essential Tools for Precision Metal Cutting

2024/05/11 -

Understanding the Role and Function of Steel Strip Slitting Machines

2024/05/11

-

A Guide to the Latest Innovations in Sheet Metal Folding Machines

2024/11/29 -

Key Features to Consider When Investing in a Sheet Metal Folding Machine

2024/11/28 -

Enhancing Precision with Advanced Sheet Metal Folding Machines

2024/11/27 -

How to Choose the Right Sheet Metal Folding Machine for Your Workshop

2024/11/26