Sheet Metal Forming Machine: The Art of Precision with METMAC Technology

- By:Metmac

- 2025-11-26

- 99

Sheet Metal Forming Machine: The Art of Precision with METMAC Technology

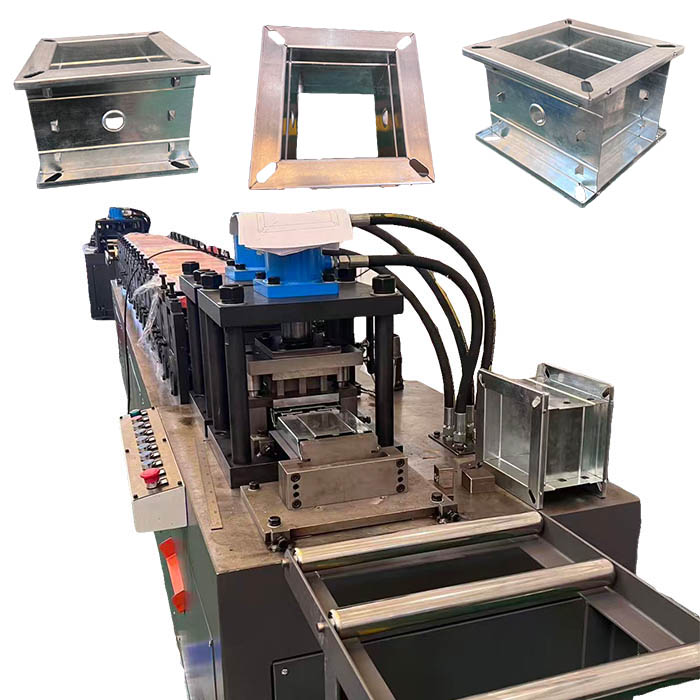

Sheet Metal Forming Machine

The transformation of a flat, inert sheet of metal into a complex, functional component is nothing short of industrial alchemy. At the heart of this transformation lies the sheet metal forming machine, a category of equipment where power, precision, and innovation converge. For manufacturers and fabricators who refuse to compromise on quality, the choice of forming technology is paramount. It dictates the limits of their creativity, the efficiency of their production, and the integrity of their final product. In this demanding field, one name has become synonymous with reliability and advanced engineering: METMAC.

Understanding the capabilities of a modern sheet metal forming machine goes beyond simply knowing its tonnage or bend length. It’s about comprehending how the machine interacts with the material, how it controls force and movement, and how it translates digital designs into physical perfection. This is the realm where METMAC excels, offering a suite of machines that empower workshops to push the boundaries of what’s possible.

The Core of Modern Fabrication: What is Sheet Metal Forming?

Sheet metal forming is the collective term for a wide range of manufacturing processes where force is applied to a sheet of metal to plastically deform it into a desired shape without removing material. Unlike machining, which is subtractive, forming is a transformative process that leverages the metal’s inherent ductility. Key processes include:

- Bending: The most common forming operation, where the metal is strained around a straight axis using a press brake.

- Stamping: Using a press and a die to create features, indentations, or complete shapes in a single stroke.

- Deep Drawing: Forming a sheet metal blank into a hollow or concave shape, like a cup or enclosure.

- Roll Forming: Continuously bending a long strip of sheet metal through a series of rolls to create complex cross-sectional profiles.

Each of these processes places unique demands on the machinery, requiring a blend of brute strength and delicate control. A generic sheet metal forming machine may be able to bend metal, but a METMAC machine is engineered to do it with unparalleled repeatability, accuracy, and efficiency.

The METMAC Difference: Engineering Precision for Every Project

What separates a METMAC sheet metal forming machine from the rest of the market is a foundational commitment to technological superiority. This is evident in every aspect of their design and construction.

1. Unmatched Control and Accuracy:

Precision in forming is not a luxury; it is a necessity. METMAC press brakes, the flagship of their forming line, are equipped with advanced CNC controls that allow operators to program complex bending sequences with ease. The synchronization of the hydraulic ram is precise, ensuring that the bend angle is consistent across the entire length of the workpiece, from the first part to the thousandth. This eliminates costly errors and rework, ensuring that every component meets strict dimensional tolerances.

2. Robustness That Withstands the Test of Time:

A sheet metal forming machine is a long-term investment. METMAC builds its machines with heavily reinforced frames and high-quality components to withstand the immense stresses of daily operation. This robust construction does more than just prevent breakdowns; it ensures that the machine’s accuracy is maintained year after year. A rigid frame minimizes deflection during bending, which is critical for achieving precise angles and avoiding the dreaded “banana” bend in long parts.

3. Versatility to Handle Diverse Demands:

No two fabricators are alike. One workshop might be producing delicate electronic enclosures from aluminum, while another is forming thick steel plates for structural applications. METMAC offers a range of sheet metal forming machines with varying tonnages, bed lengths, and capabilities. This versatility means that whether you are involved in prototyping, high-volume production, or heavy-industrial fabrication, there is a METMAC machine engineered for your specific needs. Their machines handle a wide array of materials, from stainless steel and mild steel to aluminum and copper alloys, with consistent results.

4. Operator-Centric Design for Enhanced Productivity:

METMAC understands that a machine is only as good as the person operating it. Their sheet metal forming machine interfaces are designed with intuitive software and ergonomic controls. Features like automatic tool setting, bend sequence simulation, and graphical programming reduce setup time and minimize the potential for operator error. This allows skilled fabricators to focus on the craft rather than fighting with a complicated machine, leading to higher overall productivity and job satisfaction.

Applications: Powering Industries with Precision Forming

The impact of a reliable sheet metal forming machine is felt across countless industries. METMAC equipment is the driving force behind innovation and production in:

- Aerospace and Aviation: Forming precise components where tolerances are measured in thousandths of an inch and material integrity is non-negotiable.

- Automotive Manufacturing: Creating everything from robust chassis parts to intricate brackets with high repeatability for assembly lines.

- Construction and Architecture: Producing custom cladding, structural elements, and decorative features that define modern buildings.

- Electronics and Enclosures: Fabricating shielded cabinets, server racks, and custom housings that require clean lines and perfect fits.

Beyond the Machine: The METMAC Partnership

Choosing a METMAC sheet metal forming machine is the first step in a lasting partnership. METMAC supports its clients with comprehensive service, training, and access to a global network of technical experts. This ensures that your investment is protected and that your operations continue to run smoothly, maximizing uptime and profitability.

In conclusion, while many companies sell sheet metal forming machines, METMAC delivers engineered solutions. They provide the precision, durability, and intelligent technology that modern fabricators need to compete and excel in a global market. It’s an investment not just in a piece of equipment, but in the future capability and reputation of your workshop.

To discover how a METMAC sheet metal forming machine can transform your fabrication capabilities, visit www.metmac.com and explore the technology that sets the standard for the industry.

-

2027 Essential Guide to Choosing the Perfect Bold**Wood and Fabric Bed Frame** for Your Bedroom

2026/03/05 -

2027 Latest Trends in Wood and Fabric Bed Frames for Modern Bedrooms: Comprehensive Buyer’s Guide & Top Styles Breakdown

2026/03/05 -

Wood and Fabric Bed Frames: Pros, Cons, and 2027 Maintenance Tips You Need to Know

2026/03/05 -

Iron Sheet Laser Cutting Machine: Unmatched Precision for Demanding Fabrication with METMAC

2026/01/06

-

Advanced Sheet Metal Rolling, Laser Cutting, and Folding Machines for Precision Fabrication

2025/10/31 -

High-Performance Sheet Metal Bending and Cutting Machines for Modern Fabrication

2025/10/31 -

High-Quality Sheet Metal Equipment for Sale: Efficient Solutions for Modern Manufacturing

2025/10/31 -

High-Performance Sheet Metal Equipment for Sale: Forming and Shearing Solutions for Modern Fabrication

2025/10/22

-

A Guide to the Latest Innovations in Sheet Metal Folding Machines

2024/11/29 -

Key Features to Consider When Investing in a Sheet Metal Folding Machine

2024/11/28 -

Enhancing Precision with Advanced Sheet Metal Folding Machines

2024/11/27 -

How to Choose the Right Sheet Metal Folding Machine for Your Workshop

2024/11/26