Precision Sheet Metal Cutting and Processing Machines for Modern Manufacturing

- By:Metmac

- 2025-09-25

- 108

Efficient and accurate cutting of sheet metal is essential for modern manufacturing industries. A sheet metal CNC laser cutting machine provides advanced capabilities for precise and repeatable cuts. By integrating computer numerical control (CNC) with high-powered lasers, these machines can produce complex shapes and patterns on various metals, ensuring high accuracy and minimal material waste. CNC laser cutting is widely used in automotive, aerospace, construction, and electronics industries for its precision and versatility.

A sheet metal fiber laser cutting machine offers further advantages, especially when dealing with thin or reflective metals. Fiber laser technology provides higher cutting speeds, excellent beam quality, and reduced maintenance compared to traditional CO2 lasers. This type of machine is ideal for achieving smooth edges and intricate designs with minimal heat-affected zones, making it suitable for high-precision fabrication tasks. The energy efficiency and long lifespan of fiber lasers also make them a cost-effective choice for continuous production.

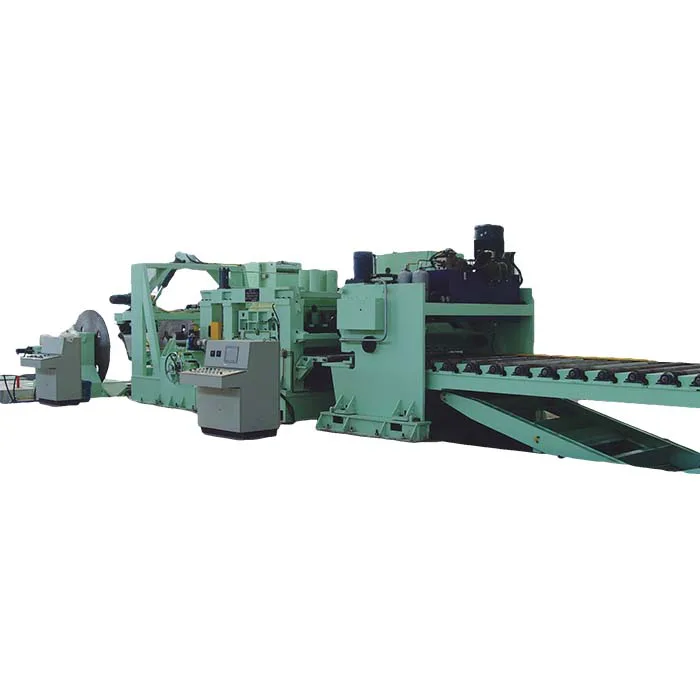

For manufacturers requiring accurate sizing of metal sheets before further processing, a sheet metal cut to length machine is an essential tool. These machines allow precise cutting of coils or large sheets into specific lengths, preparing materials for downstream processes such as bending, forming, or welding. Accurate cut-to-length operations reduce material waste, save production time, and ensure uniformity across batches, which is critical in high-volume manufacturing environments.

Metmac offers a wide range of sheet metal processing solutions, combining CNC laser cutting, fiber laser cutting, and cut-to-length technologies. These machines are designed for durability, ease of operation, and automation integration. Advanced control systems, robust construction, and customizable options allow manufacturers to optimize production efficiency while maintaining high-quality standards.

Investing in a sheet metal CNC laser cutting machine, sheet metal fiber laser cutting machine, or sheet metal cut to length machine provides multiple benefits. Manufacturers achieve higher productivity, reduced material waste, and consistent results across production batches. These machines also support complex design capabilities, enabling companies to meet diverse market demands and innovate in product development.

By combining precision cutting and efficient material handling, manufacturers can streamline their sheet metal production processes. These machines ensure reliability, repeatability, and cost-effectiveness, making them indispensable for modern fabrication workshops and industrial production lines.

-

Iron Sheet Laser Cutting Machine: Unmatched Precision for Demanding Fabrication with METMAC

2026/01/06 -

Precision Metal Cutting Machine: The Engine of Modern Manufacturing, Powered by METMAC

2026/01/06 -

Sheet Metal CNC Laser Cutting Machine: Precision Redefined with METMAC Technology

2026/01/06 -

Sheet Metal Press Brake for Sale: Find Your Precision Bending Solution with METMAC

2026/01/06

-

Advanced Sheet Metal Rolling, Laser Cutting, and Folding Machines for Precision Fabrication

2025/10/31 -

High-Performance Sheet Metal Bending and Cutting Machines for Modern Fabrication

2025/10/31 -

High-Quality Sheet Metal Equipment for Sale: Efficient Solutions for Modern Manufacturing

2025/10/31 -

High-Performance Sheet Metal Equipment for Sale: Forming and Shearing Solutions for Modern Fabrication

2025/10/22

-

A Guide to the Latest Innovations in Sheet Metal Folding Machines

2024/11/29 -

Key Features to Consider When Investing in a Sheet Metal Folding Machine

2024/11/28 -

Enhancing Precision with Advanced Sheet Metal Folding Machines

2024/11/27 -

How to Choose the Right Sheet Metal Folding Machine for Your Workshop

2024/11/26