Precision Sheet Metal Bending and Cutting Machines for Industrial Fabrication

- By:Metmac

- 2025-07-17

- 111

High-performance metalworking machinery is essential for modern fabrication workshops and industrial production lines. A reliable sheet metal bending machine plays a crucial role in shaping metal components with accuracy, speed, and consistency. Whether for HVAC ductwork, enclosures, panels, or custom components, bending machines offer the flexibility needed to meet complex production demands.

A sheet bending machine is designed to create precise angles and folds in a variety of metals, including stainless steel, galvanized sheet, aluminum, and mild steel. These machines are available in different types—from manual folding machines to hydraulic and CNC-controlled press brakes. Depending on the application, fabricators can choose the best configuration based on thickness capacity, bending length, and automation level.

Metmac’s range of bending equipment includes solutions that cater to small-scale workshops as well as large-scale industrial manufacturing. Built for stability and repeatable performance, their machines feature robust frames, precision control systems, and intuitive operation interfaces. This ensures that even complex bending tasks can be completed efficiently, with minimal setup time and reduced material waste.

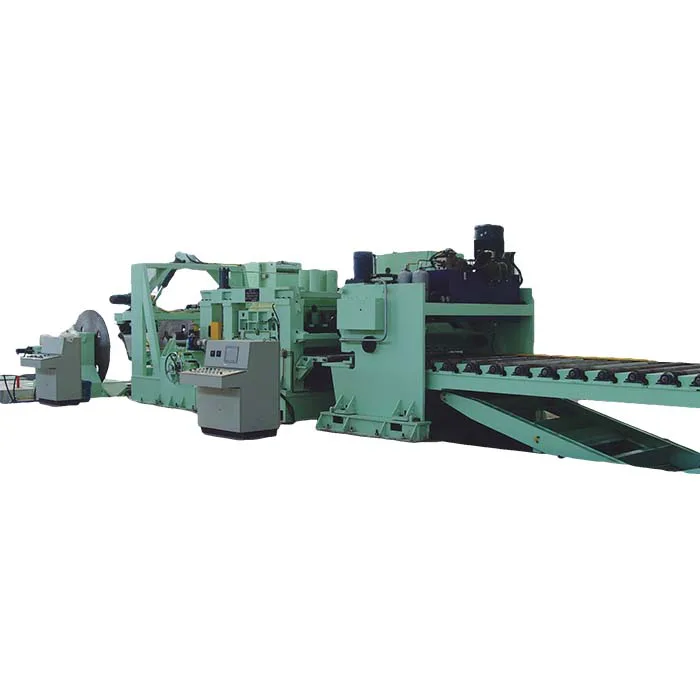

In addition to bending, cutting is a foundational process in metal fabrication. A dependable sheet metal cutting machine ensures clean, accurate cuts essential for further forming or welding operations. Shearing machines, slitting lines, and CNC cutting systems are widely used for various materials and thicknesses. These machines support consistent quality across large production volumes while keeping operational costs low.

Combining cutting and bending capabilities allows workshops to streamline their production process. For example, using a cutting machine to prepare blanks followed by a sheet bending machine to form final shapes minimizes handling and accelerates turnaround time. This integrated workflow is particularly valuable in HVAC production, cabinet making, elevator fabrication, and construction industries.

Durability, precision, and ease of maintenance are key factors when selecting any sheet metal machine. Leading manufacturers focus on high-strength components, wear-resistant surfaces, and user-friendly control systems. Advanced safety features and energy-efficient drives also contribute to a more productive and secure working environment.

Customization is another advantage in the modern sheet metal machinery industry. Whether it’s adjusting bending angles, programming cutting lengths, or modifying machine structure to fit a specific plant layout, flexibility in design helps businesses stay competitive and adaptable to customer needs.

By investing in a quality sheet metal bending machine or sheet metal cutting machine, manufacturers gain greater control over production quality, reduce reliance on outsourcing, and enhance overall efficiency. This results in faster project delivery, tighter tolerances, and long-term cost savings.

In conclusion, a well-equipped fabrication facility requires both precise cutting and bending systems. Choosing the right sheet bending machine and supporting technologies ensures superior performance across diverse metalworking applications, setting the foundation for sustainable growth in the metal fabrication industry.

-

Iron Sheet Laser Cutting Machine: Unmatched Precision for Demanding Fabrication with METMAC

2026/01/06 -

Precision Metal Cutting Machine: The Engine of Modern Manufacturing, Powered by METMAC

2026/01/06 -

Sheet Metal CNC Laser Cutting Machine: Precision Redefined with METMAC Technology

2026/01/06 -

Sheet Metal Press Brake for Sale: Find Your Precision Bending Solution with METMAC

2026/01/06

-

Advanced Sheet Metal Rolling, Laser Cutting, and Folding Machines for Precision Fabrication

2025/10/31 -

High-Performance Sheet Metal Bending and Cutting Machines for Modern Fabrication

2025/10/31 -

High-Quality Sheet Metal Equipment for Sale: Efficient Solutions for Modern Manufacturing

2025/10/31 -

High-Performance Sheet Metal Equipment for Sale: Forming and Shearing Solutions for Modern Fabrication

2025/10/22

-

Understanding the Role and Function of Steel Strip Slitting Machines

2024/05/11 -

Maintenance Tips for Longevity of HVAC Duct Machines

2024/05/11 -

Innovations in Steel Strip Slitting Machine Design and Technology

2024/05/11 -

Improving Accuracy in Metal Fabrication with Laser Metal Shear Machines

2024/05/11

-

A Guide to the Latest Innovations in Sheet Metal Folding Machines

2024/11/29 -

Key Features to Consider When Investing in a Sheet Metal Folding Machine

2024/11/28 -

Enhancing Precision with Advanced Sheet Metal Folding Machines

2024/11/27 -

How to Choose the Right Sheet Metal Folding Machine for Your Workshop

2024/11/26