Precision and Value: Exploring Metal Sheet Cutting and Roll Forming Machines

- By:Metmac

- 2025-09-06

- 90

Manufacturers across industries such as construction, automotive, and machinery rely on advanced equipment to process metal sheets with precision and efficiency. Selecting the right machines not only improves production quality but also reduces costs and downtime. For businesses planning investments, understanding metal sheet cutting machine price, available technologies, and the advantages of sheet metal roll forming machines is essential.

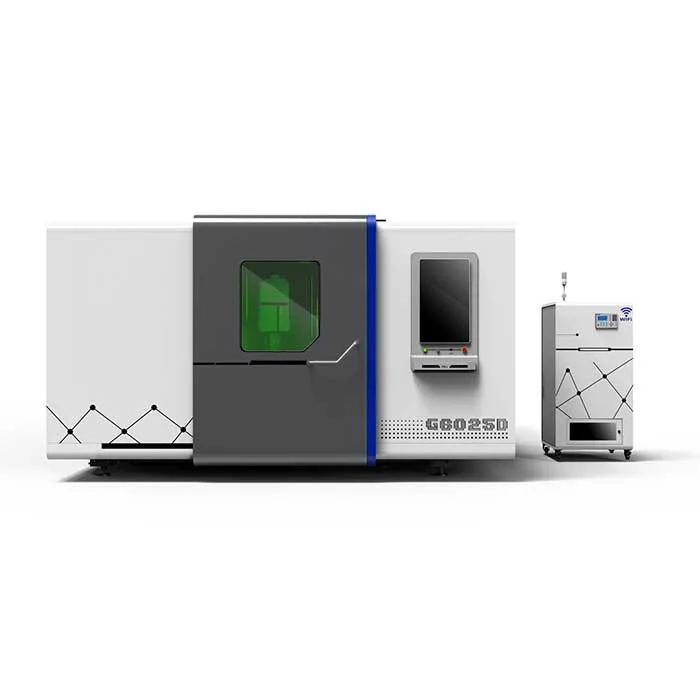

A reliable sheet metal laser cutting machine provides unmatched accuracy, speed, and versatility. Laser technology allows operators to cut complex shapes and fine details without secondary processing. The sheet metal laser cutting machine price varies depending on capacity, cutting speed, laser power, and additional automation features. While higher-power models may have a larger upfront cost, they often deliver better long-term value by handling thicker materials and achieving faster production cycles.

For those seeking entry-level solutions, traditional cutting machines remain cost-effective and reliable for standard applications. However, investing in laser systems ensures cleaner edges, reduced material waste, and more flexibility in production. Evaluating your specific production needs and material types helps determine the right balance between price and performance.

Beyond cutting, many manufacturers require forming equipment to shape sheet metal into finished components. Sheet metal roll forming machines are indispensable for producing consistent profiles such as panels, roofing sheets, and structural components. These machines work by gradually bending metal sheets through multiple rollers, delivering precise and repeatable results. With customizable tooling, they can accommodate different thicknesses and materials, offering high output and low error rates.

One of the biggest advantages of roll forming is its efficiency in large-scale production. Unlike press braking, which processes one bend at a time, roll forming machines continuously shape the material, significantly increasing throughput. This makes them ideal for industries requiring high volumes of uniform products.

When considering investments in cutting and forming equipment, it is important to evaluate not only the metal sheet cutting machine price but also operating costs, maintenance requirements, and potential productivity gains. Machines designed with modern automation and user-friendly controls help reduce labor demands and training time, ensuring a faster return on investment.

By choosing advanced sheet metal laser cutting machines and sheet metal roll forming machines, manufacturers can achieve higher precision, faster production, and consistent quality across projects. Whether producing custom parts or high-volume components, the right equipment ensures long-term competitiveness and operational efficiency.

-

Iron Sheet Laser Cutting Machine: Unmatched Precision for Demanding Fabrication with METMAC

2026/01/06 -

Precision Metal Cutting Machine: The Engine of Modern Manufacturing, Powered by METMAC

2026/01/06 -

Sheet Metal CNC Laser Cutting Machine: Precision Redefined with METMAC Technology

2026/01/06 -

Sheet Metal Press Brake for Sale: Find Your Precision Bending Solution with METMAC

2026/01/06

-

Advanced Sheet Metal Rolling, Laser Cutting, and Folding Machines for Precision Fabrication

2025/10/31 -

High-Performance Sheet Metal Bending and Cutting Machines for Modern Fabrication

2025/10/31 -

High-Quality Sheet Metal Equipment for Sale: Efficient Solutions for Modern Manufacturing

2025/10/31 -

High-Performance Sheet Metal Equipment for Sale: Forming and Shearing Solutions for Modern Fabrication

2025/10/22

-

Understanding the Role and Function of Steel Strip Slitting Machines

2024/05/11 -

Maintenance Tips for Longevity of HVAC Duct Machines

2024/05/11 -

Innovations in Steel Strip Slitting Machine Design and Technology

2024/05/11 -

Improving Accuracy in Metal Fabrication with Laser Metal Shear Machines

2024/05/11

-

A Guide to the Latest Innovations in Sheet Metal Folding Machines

2024/11/29 -

Key Features to Consider When Investing in a Sheet Metal Folding Machine

2024/11/28 -

Enhancing Precision with Advanced Sheet Metal Folding Machines

2024/11/27 -

How to Choose the Right Sheet Metal Folding Machine for Your Workshop

2024/11/26