Laser vs. Plasma vs. Waterjet Sheet Metal Cutting Machines- Which is Right for You?

- By:Metmac

- 2024-08-01

- 74

The relentless march of technological innovation has revolutionized the sheet metal cutting industry, giving rise to a captivating trinity of cutting-edge technologies: laser, plasma, and waterjet. Each wielding its own unique strengths and applications, selecting the optimal machine for your needs can be a mind-boggling labyrinth.

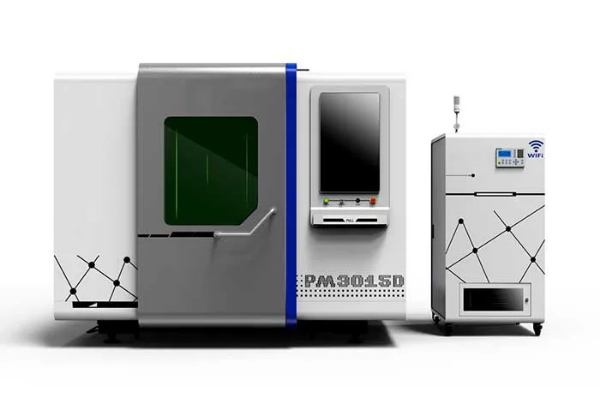

Laser Cutting: The Precision Surgeon

With a concentrated beam of coherent light, laser cutting machines deliver unparalleled precision. Their surgical accuracy makes them ideal for intricate designs and delicate materials. Moreover, their non-contact nature eliminates the need for physical contact, minimizing distortion and ensuring smooth cuts.

Pros:

– High precision and repeatability

– Minimal heat-affected zone

– Suited for complex geometries and thin materials

Cons:

– Can be slower than other methods

– Limited cutting depth

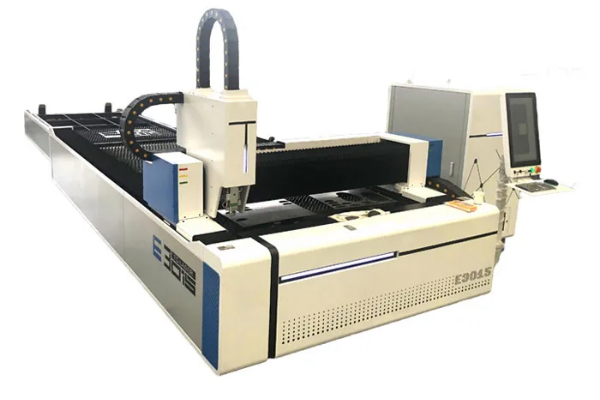

Plasma Cutting: The Powerhouse

Harnessing the intense heat of ionized gas, plasma cutting machines blaze through thicker materials like butter. Their sheer power makes them suitable for heavy-duty applications, particularly in steel fabrication and shipbuilding. Additionally, plasma cutting is cost-effective and relatively fast.

Pros:

– Fast and efficient cutting

– High cutting depths

– Cost-effective option

Cons:

– Wider heat-affected zone

– Can produce rougher cuts

Waterjet Cutting: The Versatile Workhorse

Unlike its laser and plasma counterparts, waterjet cutting utilizes a high-pressure water stream mixed with abrasive particles. This unique process allows it to cut a wide range of materials, including metals, composites, and even stone. Moreover, waterjet cutting produces no fumes or heat, making it an environmentally friendly option.

Pros:

– Versatility in material cutting

– No heat-affected zone

– Environmentally friendly

Cons:

– Slower cutting speed

– Limited cutting depths in certain materials

Which is Right for You?

The choice between laser, plasma, and waterjet cutting machines hinges on the specific requirements of your application. For precise, intricate cuts in thin materials, laser cutting reigns supreme. For hefty cutting tasks in thick metals, plasma cutting is a formidable choice. And if versatility, environmental friendliness, and cutting a range of materials are paramount, waterjet cutting is an excellent option.

Ultimately, the right cutting machine depends on the scope of your work, the materials you work with, and your desired cut quality. By understanding these factors, you can navigate the sheet metal cutting landscape with confidence and wield the power of advanced technology to empower your projects.

-

The Advantages of Using a Sheet Roll Forming Machine in Manufacturing

2024/09/14 -

How to Optimize Your Laser Sheet Cutting Machine for Maximum Performance

2024/09/12 -

How to Maximize Efficiency with Modern Sheet Metal Working Machines

2024/09/04 -

The Environmental Benefits of Using Duct Board Grooving Machines

2024/09/03

-

Efficient Sheet Metal Machinery: Rolling, Punching, and Laser Cutting Technologies Explained

2025/05/20 -

Precision and Power: The Evolution of Sheet Metal Machinery for Modern Manufacturing

2025/05/20 -

Precision Bending with Electrical Press Brakes and Sheet Metal Solutions

2025/05/20 -

Enhancing Duct Fabrication with Advanced Duct Beading and Grooving Machines

2025/05/11

-

A Guide to the Latest Innovations in Sheet Metal Folding Machines

2024/11/29 -

Key Features to Consider When Investing in a Sheet Metal Folding Machine

2024/11/28 -

Enhancing Precision with Advanced Sheet Metal Folding Machines

2024/11/27 -

How to Choose the Right Sheet Metal Folding Machine for Your Workshop

2024/11/26