Iron Cutting Laser Machine: How METMAC Delivers Unmatched Precision and Durability

- By:Metmac

- 2025-12-03

- 80

Iron Cutting Laser Machine: How METMAC Delivers Unmatched Precision and Durability

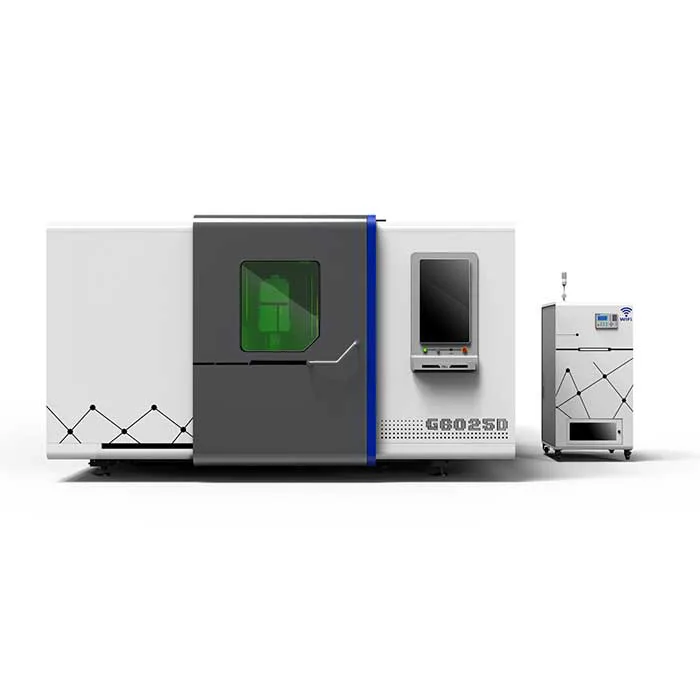

Iron Cutting Laser Machine

In the world of modern fabrication and industrial manufacturing, the ability to cut through iron with precision, speed, and efficiency is not just an advantage—it’s a necessity. As industries demand higher quality, more complex components, and faster turnaround times, the technology behind the iron cutting laser machine has become the cornerstone of progress. At the forefront of this technological revolution stands METMAC, a brand synonymous with innovation, reliability, and superior performance. Our laser cutting systems are engineered not just to meet the demands of today but to anticipate the challenges of tomorrow.

The METMAC Difference: Engineering Excellence for Demanding Applications

An iron cutting laser machine is only as good as its core components and the engineering philosophy behind it. METMAC machines are built from the ground up with a singular focus: to provide unparalleled performance in cutting ferrous metals, including mild steel, stainless steel, and other iron alloys. What sets a METMAC system apart is its perfect harmony of power, precision, and intelligence.

Our machines feature high-powered fiber laser sources known for their exceptional energy efficiency and beam quality. This translates into cleaner cuts, sharper edges, and remarkably smooth finishes on iron surfaces, significantly reducing or even eliminating the need for secondary finishing processes. The advanced cutting heads, equipped with auto-focus and collision avoidance systems, ensure consistent quality, even over long production runs and complex geometries. Whether it’s intricate decorative metalwork, heavy-duty construction parts, or precise automotive components, a METMAC laser cutter handles the task with finesse.

Unlocking Productivity with Smart Technology

Beyond raw power, the true value of a modern iron cutting laser machine lies in its intelligence and ease of use. METMAC integrates state-of-the-art CNC controls and user-friendly software interfaces to create a seamless workflow from design to finished part. Our intuitive software allows for efficient nesting of parts to minimize material waste, a critical factor in managing costs with iron plate and sheet.

Features such as real-time monitoring, predictive maintenance alerts, and remote diagnostics ensure that your METMAC machine operates at peak efficiency with minimal downtime. This smart connectivity empowers operators to maximize productivity and gives managers unparalleled oversight into the production process. By reducing manual intervention and optimizing every cut path, we help businesses significantly boost their output and improve their bottom line.

Durability Built for the Long Haul

Industrial equipment must withstand the rigors of a demanding workshop environment. METMAC understands this fundamentally. Our iron cutting laser machines are housed in robust, rigid frames constructed from high-grade materials to ensure exceptional stability and vibration damping. This structural integrity is crucial for maintaining micron-level accuracy over years of operation.

Furthermore, we employ top-tier linear guides, precision drive systems, and advanced cooling technologies to protect critical components from the heat and stress of continuous operation. This commitment to durable construction means a METMAC machine is not merely a purchase; it’s a long-term capital investment that delivers consistent return through reliable, day-in, day-out performance.

A Partner in Your Growth

Choosing METMAC goes beyond selecting a machine; it’s choosing a partner committed to your success. We provide comprehensive support, including expert training for your team, readily available spare parts, and responsive technical service. Our application specialists work with you to understand your specific needs, whether you are a job shop catering to diverse clients or a large manufacturer with specialized production lines.

Conclusion: Cutting-Edge Performance, Powered by METMAC

In the competitive landscape of metal fabrication, the right tools define your capability. For businesses that rely on cutting iron and steel with uncompromising quality, speed, and reliability, the choice is clear. The METMAC iron cutting laser machine represents the pinnacle of laser cutting technology—a blend of robust engineering, intelligent software, and unwavering durability.

It is designed for those who refuse to compromise, who seek to elevate their craft, and who aim to lead their industry. Discover how METMAC can transform your production capabilities. Visit www.metmac.com to explore our range of fiber laser cutting solutions and learn how we can help you cut deeper into the future of manufacturing. With METMAC, you’re not just cutting iron; you’re carving a path to greater innovation and productivity.

-

2027 Essential Guide to Choosing the Perfect Bold**Wood and Fabric Bed Frame** for Your Bedroom

2026/03/05 -

2027 Latest Trends in Wood and Fabric Bed Frames for Modern Bedrooms: Comprehensive Buyer’s Guide & Top Styles Breakdown

2026/03/05 -

Wood and Fabric Bed Frames: Pros, Cons, and 2027 Maintenance Tips You Need to Know

2026/03/05 -

Iron Sheet Laser Cutting Machine: Unmatched Precision for Demanding Fabrication with METMAC

2026/01/06

-

Advanced Sheet Metal Rolling, Laser Cutting, and Folding Machines for Precision Fabrication

2025/10/31 -

High-Performance Sheet Metal Bending and Cutting Machines for Modern Fabrication

2025/10/31 -

High-Quality Sheet Metal Equipment for Sale: Efficient Solutions for Modern Manufacturing

2025/10/31 -

High-Performance Sheet Metal Equipment for Sale: Forming and Shearing Solutions for Modern Fabrication

2025/10/22

-

A Guide to the Latest Innovations in Sheet Metal Folding Machines

2024/11/29 -

Key Features to Consider When Investing in a Sheet Metal Folding Machine

2024/11/28 -

Enhancing Precision with Advanced Sheet Metal Folding Machines

2024/11/27 -

How to Choose the Right Sheet Metal Folding Machine for Your Workshop

2024/11/26