High-Precision Solutions from Leading Sheet Metal Cutting Machine Manufacturers

- By:Metmac

- 2025-09-11

- 138

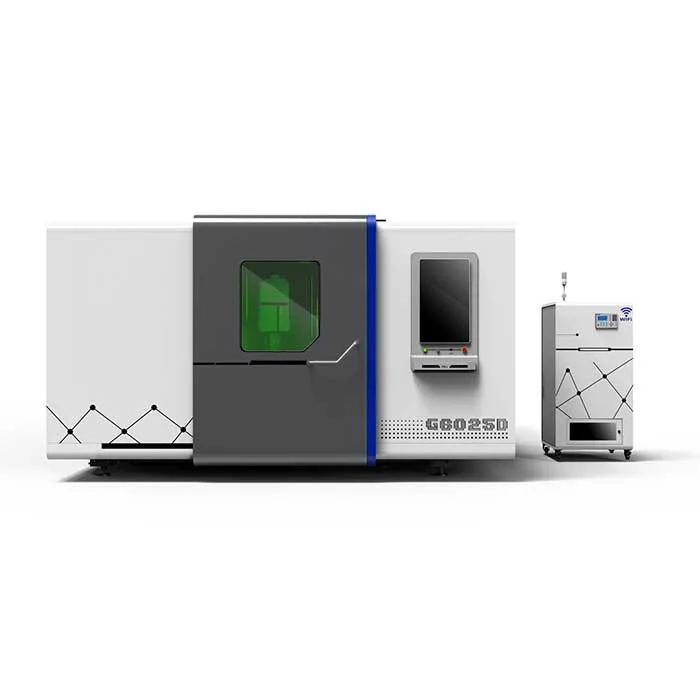

CNC technology has transformed the way industries work with sheet metal. A CNC laser cutting machine sheet metal system offers accuracy, speed, and versatility that traditional methods cannot match. Whether for automotive components, construction materials, or custom fabrication, these machines help manufacturers achieve clean cuts, intricate shapes, and consistent quality.

One of the biggest advantages of a sheet metal laser cutting machine is its ability to handle complex designs without compromising on precision. Advanced laser systems use computer numerical control to direct powerful beams with pinpoint accuracy. This results in smooth edges, minimal waste, and reduced finishing requirements. The technology is especially valuable for industries that rely on tight tolerances and efficient production workflows.

For heavy-duty cutting tasks, a plasma sheet metal cutting machine offers another strong option. Plasma technology uses ionized gas to cut through conductive materials at high speed. It is well-suited for thicker sheets and applications where productivity is just as important as accuracy. Many manufacturers combine both laser and plasma machines to cover a wide range of sheet metal cutting needs, ensuring flexibility in different production environments.

When evaluating sheet metal laser cutting machine manufacturers, buyers often consider factors such as build quality, automation features, and service support. Machines designed with durable frames, advanced motion control systems, and intelligent software integration help ensure long-term reliability. Automation options, including material handling systems and nesting software, further improve efficiency by reducing manual labor and material waste.

Metmac, as a trusted manufacturer in the sheet metal machinery industry, provides a comprehensive range of cutting solutions designed to meet diverse production demands. The product line includes high-performance CNC laser cutting machine sheet metal systems as well as robust plasma sheet metal cutting machines, all engineered with precision and efficiency in mind. Customers benefit from a focus on innovation, user-friendly interfaces, and dependable after-sales support.

Choosing the right sheet metal cutting machine depends on production requirements. For fine detail and high precision, laser cutting remains the preferred choice. For fast cutting of thicker materials at lower cost, plasma systems deliver strong results. Many companies invest in both technologies to maximize capability and remain competitive in a demanding market.

As industries continue to advance, the role of reliable sheet metal laser cutting machine manufacturers becomes even more important. High-quality machines help businesses streamline production, improve product quality, and reduce operational costs. By investing in advanced technology from established suppliers, manufacturers gain the confidence to meet current demands while preparing for future growth.

-

2027 Essential Guide to Choosing the Perfect Bold**Wood and Fabric Bed Frame** for Your Bedroom

2026/03/05 -

2027 Latest Trends in Wood and Fabric Bed Frames for Modern Bedrooms: Comprehensive Buyer’s Guide & Top Styles Breakdown

2026/03/05 -

Wood and Fabric Bed Frames: Pros, Cons, and 2027 Maintenance Tips You Need to Know

2026/03/05 -

Iron Sheet Laser Cutting Machine: Unmatched Precision for Demanding Fabrication with METMAC

2026/01/06

-

Advanced Sheet Metal Rolling, Laser Cutting, and Folding Machines for Precision Fabrication

2025/10/31 -

High-Performance Sheet Metal Bending and Cutting Machines for Modern Fabrication

2025/10/31 -

High-Quality Sheet Metal Equipment for Sale: Efficient Solutions for Modern Manufacturing

2025/10/31 -

High-Performance Sheet Metal Equipment for Sale: Forming and Shearing Solutions for Modern Fabrication

2025/10/22

-

Integrating Automation with Rectangular Duct Machines for Enhanced Productivity

2024/05/11 -

Metal Shear Machines- Essential Tools for Precision Metal Cutting

2024/05/11 -

Understanding the Role and Function of Steel Strip Slitting Machines

2024/05/11 -

Maintenance Tips for Longevity of HVAC Duct Machines

2024/05/11

-

A Guide to the Latest Innovations in Sheet Metal Folding Machines

2024/11/29 -

Key Features to Consider When Investing in a Sheet Metal Folding Machine

2024/11/28 -

Enhancing Precision with Advanced Sheet Metal Folding Machines

2024/11/27 -

How to Choose the Right Sheet Metal Folding Machine for Your Workshop

2024/11/26