Efficient Sheet Metal Working Machines for Modern Manufacturing

- By:Metmac

- 2025-09-17

- 174

High-quality metal fabrication requires reliable and precise machinery. Professional sheet metal working machines play a crucial role in modern manufacturing by enabling accurate cutting, bending, and forming of metal sheets. These machines are designed to improve productivity, reduce material waste, and ensure consistent quality across all production processes. Partnering with experienced suppliers ensures access to durable machinery, technical support, and tailored solutions for diverse industrial needs.

A sheet roll forming machine is an essential tool for producing long, uniform metal profiles efficiently. Roll forming machines work by gradually shaping metal sheets through a series of rollers, allowing manufacturers to achieve complex cross-sectional designs with minimal material waste. These machines are ideal for creating components for construction, automotive, and appliance industries. Suppliers with expertise in roll forming technology provide machines that combine precision, speed, and durability, helping businesses optimize production and maintain high-quality standards.

In addition to individual machines, complete sheet metal roll forming machines lines offer integrated solutions for large-scale production. These systems can handle continuous processing of metal sheets, producing consistent and repeatable profiles while minimizing manual intervention. Modern roll forming machines often include features such as automated feeding, cutting, and quality inspection, streamlining workflow and reducing labor costs. By choosing advanced roll forming equipment, manufacturers can enhance efficiency, accuracy, and overall operational performance.

Working with a reliable supplier ensures that all machinery meets international standards for quality and safety. Experienced sheet metal working machine manufacturers provide technical guidance, installation support, and after-sales service, which extends the operational life of the machines and maximizes return on investment. Customization options are also available, allowing businesses to adapt machines to specific project requirements and production capacities.

Sustainability and cost-efficiency are additional advantages of modern sheet metal working machines. Energy-efficient designs and precise forming processes reduce operational costs and material waste. By investing in high-quality sheet roll forming machines and complete sheet metal roll forming machine lines, manufacturers can improve production output, maintain superior quality, and achieve long-term operational success.

-

2027 Essential Guide to Choosing the Perfect Bold**Wood and Fabric Bed Frame** for Your Bedroom

2026/03/05 -

2027 Latest Trends in Wood and Fabric Bed Frames for Modern Bedrooms: Comprehensive Buyer’s Guide & Top Styles Breakdown

2026/03/05 -

Wood and Fabric Bed Frames: Pros, Cons, and 2027 Maintenance Tips You Need to Know

2026/03/05 -

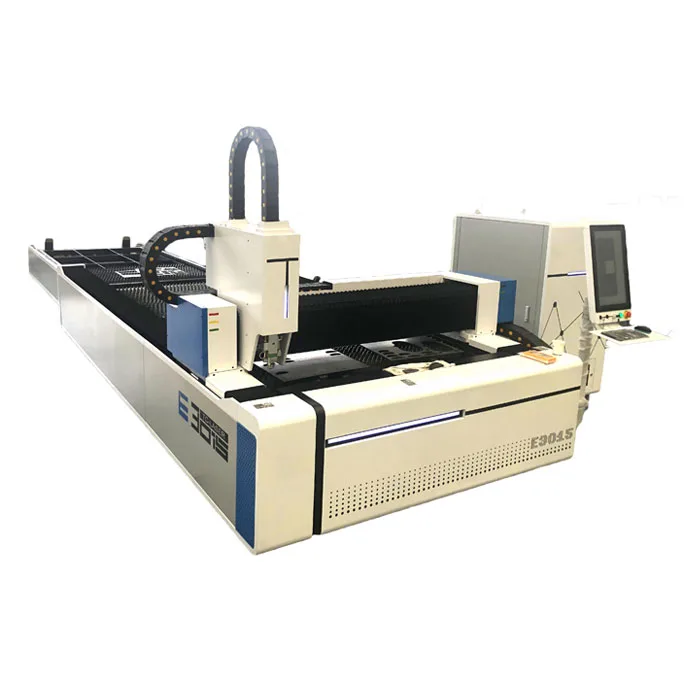

Iron Sheet Laser Cutting Machine: Unmatched Precision for Demanding Fabrication with METMAC

2026/01/06

-

Advanced Sheet Metal Rolling, Laser Cutting, and Folding Machines for Precision Fabrication

2025/10/31 -

High-Performance Sheet Metal Bending and Cutting Machines for Modern Fabrication

2025/10/31 -

High-Quality Sheet Metal Equipment for Sale: Efficient Solutions for Modern Manufacturing

2025/10/31 -

High-Performance Sheet Metal Equipment for Sale: Forming and Shearing Solutions for Modern Fabrication

2025/10/22

-

Understanding the Role and Function of Steel Strip Slitting Machines

2024/05/11 -

Maintenance Tips for Longevity of HVAC Duct Machines

2024/05/11 -

Innovations in Steel Strip Slitting Machine Design and Technology

2024/05/11 -

Improving Accuracy in Metal Fabrication with Laser Metal Shear Machines

2024/05/11

-

A Guide to the Latest Innovations in Sheet Metal Folding Machines

2024/11/29 -

Key Features to Consider When Investing in a Sheet Metal Folding Machine

2024/11/28 -

Enhancing Precision with Advanced Sheet Metal Folding Machines

2024/11/27 -

How to Choose the Right Sheet Metal Folding Machine for Your Workshop

2024/11/26