Efficiency and Precision with Electrical Press Brake Solutions

- By:Metmac

- 2025-06-06

- 118

Precision bending plays a crucial role in modern metal fabrication. From structural components to intricate sheet parts, manufacturers rely on high-performance equipment to meet the demands of accuracy, repeatability, and speed. The electrical press brake has become a preferred solution in this space, offering energy-efficient operation and superior control compared to traditional systems.

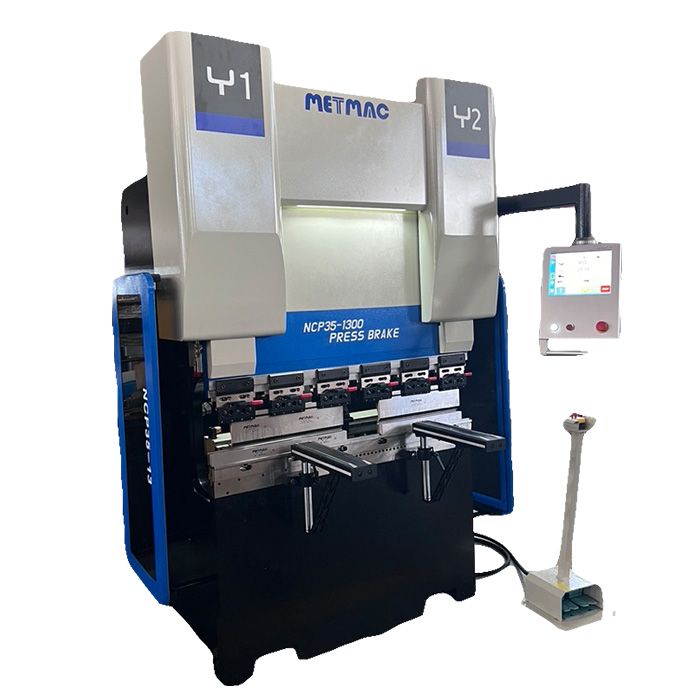

Metmac’s range of electrical press brakes is engineered to deliver consistent, clean bends across a variety of materials and thicknesses. Unlike hydraulic systems, electrical models use servo motors to apply force, resulting in more precise motion and significantly reduced energy consumption. This not only supports eco-friendly manufacturing practices but also cuts down on operational costs over time.

A reliable press metal machine must balance power and control. With Metmac’s machines, users benefit from intuitive programming systems, allowing even complex multi-step bends to be performed with minimal manual intervention. Advanced control panels offer real-time feedback and precise angle adjustments, giving fabricators the confidence to take on custom or high-volume jobs with accuracy.

These machines are ideal for bending mild steel, stainless steel, aluminum, and other sheet metals. Their sturdy frames and high-quality components ensure minimal deflection and vibration, which is essential for maintaining tight tolerances. The sheet metal press brake lineup from Metmac also includes options with CNC capabilities, making them well-suited for repetitive tasks and production workflows that demand consistency.

Beyond performance, safety and usability are top priorities. Built-in safety features such as light curtains, emergency stops, and two-hand controls protect operators without compromising productivity. Ergonomic designs and user-friendly software interfaces reduce operator fatigue and training time, making these machines accessible even to new users.

Flexibility is another strength of electrical press brakes. Tooling can be quickly changed to accommodate different shapes, and multiple machine configurations are available to suit varying factory layouts. Whether it’s a compact unit for a small shop or a high-tonnage model for industrial-scale bending, there’s a solution to fit every application.

Investing in a modern press brake doesn’t just upgrade your equipment—it transforms your entire fabrication process. The combination of faster setup, quieter operation, and increased precision allows manufacturers to deliver higher-quality products to market faster and with lower costs.

For those seeking a durable, low-maintenance, and highly efficient sheet metal press brake, Metmac’s machines stand out as a smart long-term investment. With strong engineering, dependable support, and proven performance, these solutions meet the needs of evolving manufacturing environments.

-

Iron Sheet Laser Cutting Machine: Unmatched Precision for Demanding Fabrication with METMAC

2026/01/06 -

Precision Metal Cutting Machine: The Engine of Modern Manufacturing, Powered by METMAC

2026/01/06 -

Sheet Metal CNC Laser Cutting Machine: Precision Redefined with METMAC Technology

2026/01/06 -

Sheet Metal Press Brake for Sale: Find Your Precision Bending Solution with METMAC

2026/01/06

-

Advanced Sheet Metal Rolling, Laser Cutting, and Folding Machines for Precision Fabrication

2025/10/31 -

High-Performance Sheet Metal Bending and Cutting Machines for Modern Fabrication

2025/10/31 -

High-Quality Sheet Metal Equipment for Sale: Efficient Solutions for Modern Manufacturing

2025/10/31 -

High-Performance Sheet Metal Equipment for Sale: Forming and Shearing Solutions for Modern Fabrication

2025/10/22

-

A Guide to the Latest Innovations in Sheet Metal Folding Machines

2024/11/29 -

Key Features to Consider When Investing in a Sheet Metal Folding Machine

2024/11/28 -

Enhancing Precision with Advanced Sheet Metal Folding Machines

2024/11/27 -

How to Choose the Right Sheet Metal Folding Machine for Your Workshop

2024/11/26