Bending Brakes: The Art of Precision in Metal Forming

- By:Metmac

- 2025-11-11

- 114

Bending Brakes: The Art of Precision in Metal Forming

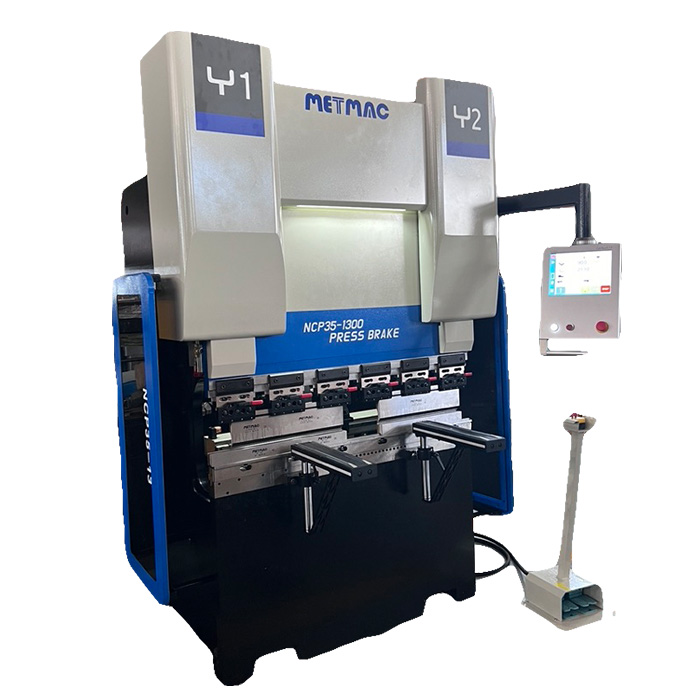

In the hands of a skilled fabricator, a sheet of metal is a canvas of possibility. The tool that turns this flat canvas into a functional, three-dimensional form is the bending brake. This fundamental piece of workshop equipment is where precision meets power, transforming raw materials into the angled brackets, enclosures, and panels that form the backbone of countless products and structures. For professionals who rely on accuracy and durability, the choice of a bending brake is critical. In this realm, the METMAC name has become synonymous with unwavering performance and engineered excellence.

The Essential Role of the Bending Brake

A bending brake, at its core, is a machine designed to create precise bends in sheet metal by clamping the material between a top jaw and a bottom bed, then lifting the bending leaf to form the desired angle. While the concept is straightforward, the execution of a perfect, consistent bend is an engineering challenge. Factors like material spring-back, thickness variation, and the sheer tonnage required demand a machine that is not just strong, but also intelligent and impeccably built.

The difference between an adequate bend and a perfect one often lies in the machine itself. A poorly constructed brake will suffer from deflection—a slight bending in the frame and bed under load—leading to inconsistent angles across the length of the workpiece, particularly on wider sheets. This inconsistency creates a domino effect of problems in assembly, fit, and finish. A METMAC bending brake is designed from the ground up to eliminate these variables, providing a solid foundation for flawless fabrication.

METMAC: Built for the Demands of Modern Fabrication

The philosophy behind every METMAC bending brake is simple: it must be the most reliable and precise tool in your shop. We understand that for metalworkers, welders, and manufacturers, time is money, and a faulty bend is a costly mistake. Our brakes are engineered for the real world, where daily use and demanding deadlines are the norm.

The hallmarks of a METMAC bending brake are what set it apart:

- Unrivaled Structural Integrity: The foundation of any precise brake is its resistance to deflection. METMAC brakes feature a box-style, fully welded construction made from high-tensile steel. This robust design is engineered to distribute the immense clamping and bending forces evenly along the entire length of the machine. The result is a perfectly straight bend from one end of the sheet to the other, whether you are working with a 4-foot or a 12-foot workpiece. This rigidity is non-negotiable for professional results.

- Precision Engineering for Flawless Bends: Every component on a METMAC brake is machined to exacting tolerances. The hinges, the clamping mechanism, and the bending leaf all work in perfect harmony to ensure smooth, repeatable operation. We offer manual models with fine-adjustment features for shops that value simplicity and strength, as well as CNC-assisted models for high-volume production that requires digital precision and repeatability. This versatility means there is a METMAC brake perfectly suited to your specific workflow and accuracy requirements.

- Operator-Focused Design and Safety: A great machine not only performs well but is also a pleasure to use. METMAC brakes are designed with the operator in mind. Features may include easy-to-read angle indicators, accessible clamping handles, and robust safety guards. By reducing operator fatigue and enhancing safety, we empower your team to work more efficiently and with greater confidence, leading to higher productivity and a better shop environment.

The Versatility of a METMAC Bending Brake

The ability to create a clean, sharp bend opens up a world of fabrication possibilities. A METMAC brake is a versatile workhorse, capable of handling a wide array of materials, including mild steel, stainless steel, aluminum, and copper.

- HVAC and Ductwork: Forming precise seams and angles for custom ducting and ventilation systems is a core application where speed and consistency are paramount.

- Metal Roofing and Cladding: Creating the consistent, sharp bends required for standing seam roofs, flashing, and trim work demands a brake that can handle long sheets with perfect accuracy.

- General Fabrication and Job Shops: From custom brackets and boxes to machine guards and architectural features, the METMAC brake is the go-to tool for turning conceptual designs into tangible, high-quality parts.

- Art and Sculpture: For metal artists, the ability to make precise, repeatable bends is essential for bringing their creative visions to life. The reliability of a METMAC brake provides the control needed for artistic expression.

More Than a Machine: The METMAC Partnership

Choosing a METMAC bending brake is an investment in your shop’s capability and reputation. We view our relationship with customers as a long-term partnership. Our support begins with helping you select the right model and capacity for your needs and continues with comprehensive installation, operator training, and unparalleled after-sales service. Our global network ensures that technical support and genuine METMAC parts are always within reach, minimizing downtime and protecting your investment for years to come.

Conclusion: The Foundation of Quality, Formed by METMAC

The bending brake is more than just a machine; it is the cornerstone of quality in a metal fabrication shop. It is the point at which a design takes its physical form. In a competitive market, the precision and reliability of your forming process are not just advantages—they are necessities.

METMAC provides the robust, accurate, and dependable equipment that professionals rely on to deliver superior results. We are committed to empowering fabricators with the tools they need to build, create, and innovate.

To see the full range of METMAC bending brakes and discover how they can become the foundation of your shop’s quality, visit us at www.metmac.com. Let us help you shape your ideas with precision.

-

Iron Sheet Laser Cutting Machine: Unmatched Precision for Demanding Fabrication with METMAC

2026/01/06 -

Precision Metal Cutting Machine: The Engine of Modern Manufacturing, Powered by METMAC

2026/01/06 -

Sheet Metal CNC Laser Cutting Machine: Precision Redefined with METMAC Technology

2026/01/06 -

Sheet Metal Press Brake for Sale: Find Your Precision Bending Solution with METMAC

2026/01/06

-

Advanced Sheet Metal Rolling, Laser Cutting, and Folding Machines for Precision Fabrication

2025/10/31 -

High-Performance Sheet Metal Bending and Cutting Machines for Modern Fabrication

2025/10/31 -

High-Quality Sheet Metal Equipment for Sale: Efficient Solutions for Modern Manufacturing

2025/10/31 -

High-Performance Sheet Metal Equipment for Sale: Forming and Shearing Solutions for Modern Fabrication

2025/10/22

-

Understanding the Role and Function of Steel Strip Slitting Machines

2024/05/11 -

Maintenance Tips for Longevity of HVAC Duct Machines

2024/05/11 -

Innovations in Steel Strip Slitting Machine Design and Technology

2024/05/11 -

Improving Accuracy in Metal Fabrication with Laser Metal Shear Machines

2024/05/11

-

A Guide to the Latest Innovations in Sheet Metal Folding Machines

2024/11/29 -

Key Features to Consider When Investing in a Sheet Metal Folding Machine

2024/11/28 -

Enhancing Precision with Advanced Sheet Metal Folding Machines

2024/11/27 -

How to Choose the Right Sheet Metal Folding Machine for Your Workshop

2024/11/26