Advanced Sheet Metal Rolling, Cutting, and Folding Machines for Efficient Fabrication

- By:Metmac

- 2025-10-22

- 131

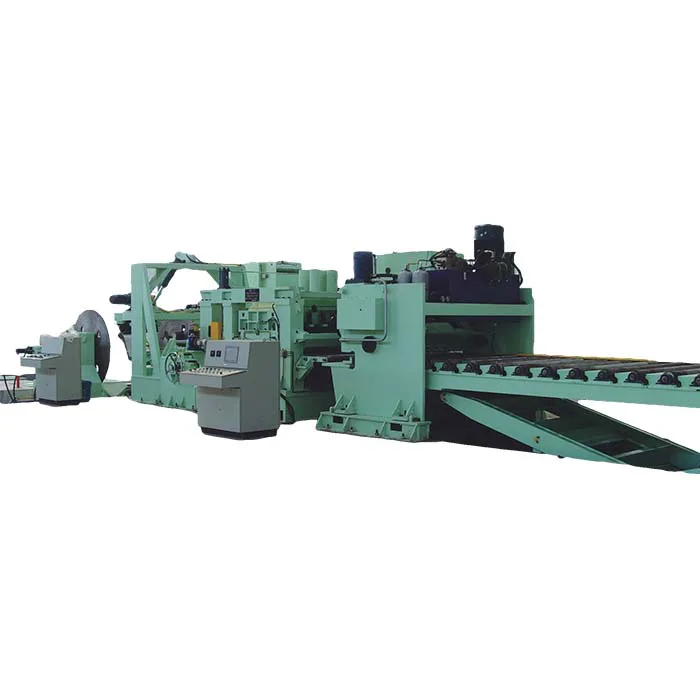

High-quality sheet metal fabrication requires precision, versatility, and reliability at every stage of production. Metmac provides advanced machinery solutions, including sheet metal rolling machines, sheet metal laser cutting machines, and sheet metal folding machines, designed to meet the growing demands of modern manufacturing industries. Whether for HVAC ducts, construction panels, or custom metal components, Metmac’s equipment delivers superior performance and accuracy.

A sheet metal rolling machine is essential for shaping flat sheets into cylindrical or curved forms used in ventilation systems, tanks, and various industrial components. Metmac’s rolling machines are engineered with durable rollers, precise adjustment mechanisms, and robust frames to ensure smooth and uniform rolling. Operators can easily control roll pressure and diameter to achieve consistent results for different materials and thicknesses. With optional automation and digital readout systems, these machines enhance efficiency and minimize material waste.

The sheet metal laser cutting machine from Metmac offers unmatched precision and cutting speed. Utilizing advanced fiber laser technology, it ensures clean, burr-free edges and high repeatability, even for complex shapes. This machine is ideal for cutting stainless steel, aluminum, and galvanized sheet materials with exceptional accuracy. Its CNC control system allows for quick programming, automatic nesting, and minimal manual intervention, helping manufacturers optimize production time and reduce operating costs. With high cutting efficiency and low maintenance requirements, the laser cutting machine is a reliable tool for any metal processing facility.

For bending and shaping operations, the sheet metal folding machine plays a key role in achieving precise angles and dimensions. Metmac’s folding machines are designed for flexibility, capable of handling a variety of sheet sizes and bending configurations. Featuring CNC control and automatic clamping systems, they enable smooth, accurate folds with consistent quality across batches. These machines are widely used for producing enclosures, doors, ducts, and other structural components that require exact folds without damaging the material surface.

When integrated into a production line, Metmac’s rolling, cutting, and folding machines form a complete solution for sheet metal processing. The combination of these technologies streamlines workflow, improves accuracy, and ensures efficient use of raw materials. Each machine is built with a focus on user safety, easy maintenance, and long-term reliability, making Metmac equipment an ideal choice for businesses aiming to enhance production capacity and quality control.

Metmac continues to innovate in the field of sheet metal machinery, offering solutions tailored to various industries and production needs. With years of experience in engineering and manufacturing, the company provides comprehensive support, from equipment selection to technical service, ensuring customers achieve consistent and high-quality results.

-

2027 Essential Guide to Choosing the Perfect Bold**Wood and Fabric Bed Frame** for Your Bedroom

2026/03/05 -

2027 Latest Trends in Wood and Fabric Bed Frames for Modern Bedrooms: Comprehensive Buyer’s Guide & Top Styles Breakdown

2026/03/05 -

Wood and Fabric Bed Frames: Pros, Cons, and 2027 Maintenance Tips You Need to Know

2026/03/05 -

Iron Sheet Laser Cutting Machine: Unmatched Precision for Demanding Fabrication with METMAC

2026/01/06

-

Advanced Sheet Metal Rolling, Laser Cutting, and Folding Machines for Precision Fabrication

2025/10/31 -

High-Performance Sheet Metal Bending and Cutting Machines for Modern Fabrication

2025/10/31 -

High-Quality Sheet Metal Equipment for Sale: Efficient Solutions for Modern Manufacturing

2025/10/31 -

High-Performance Sheet Metal Equipment for Sale: Forming and Shearing Solutions for Modern Fabrication

2025/10/22

-

A Guide to the Latest Innovations in Sheet Metal Folding Machines

2024/11/29 -

Key Features to Consider When Investing in a Sheet Metal Folding Machine

2024/11/28 -

Enhancing Precision with Advanced Sheet Metal Folding Machines

2024/11/27 -

How to Choose the Right Sheet Metal Folding Machine for Your Workshop

2024/11/26