Advanced Sheet Metal Roll Forming and Laser Cutting Machines for Efficient Production

- By:Metmac

- 2025-08-14

- 99

Manufacturers in the metalworking industry are increasingly turning to advanced machinery to boost efficiency and precision. Sheet metal roll forming machines and sheet metal laser cutting machines are essential tools that allow businesses to produce high-quality components quickly and accurately. For companies seeking sheet metal laser cutting machines for sale, working with experienced manufacturers ensures reliable performance and long-term investment value.

Sheet metal roll forming machines provide a continuous, high-speed solution for shaping metal sheets into precise profiles. These machines gradually bend metal strips through a series of rollers, creating uniform components such as roofing panels, wall claddings, and structural parts. The process minimizes waste, reduces manual labor, and ensures consistent quality across large production runs. Businesses using roll forming machines benefit from faster turnaround times and improved production efficiency, making these machines indispensable for high-volume manufacturing.

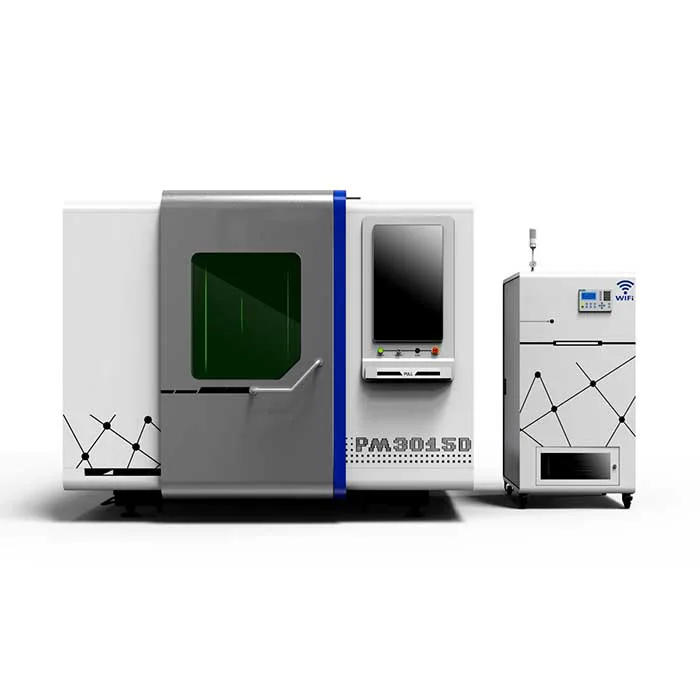

In addition to roll forming, precision cutting is critical for modern metal fabrication. Sheet metal laser cutting machine manufacturers offer advanced solutions capable of producing intricate designs with minimal error. Laser cutting technology delivers clean edges, precise dimensions, and fast processing speeds, which are particularly valuable for custom parts or complex assemblies. The ability to cut a variety of metals, including steel and aluminum, makes laser cutting machines versatile tools for diverse applications.

For businesses searching for sheet metal laser cutting machines for sale, selecting a reliable manufacturer is key. Reputable suppliers provide machines designed for durability, accuracy, and ease of use. Features such as programmable controls, automated loading systems, and integrated safety mechanisms enhance productivity while ensuring operator safety. Additionally, experienced manufacturers offer technical support, maintenance services, and training, helping buyers maximize machine performance and minimize downtime.

Combining roll forming and laser cutting machines within a production line creates a seamless workflow. Raw metal sheets can be shaped, cut, and prepared for assembly with minimal handling, reducing the risk of defects and accelerating overall production. This integrated approach allows manufacturers to meet tight deadlines and maintain consistent quality, which is essential for industries such as construction, automotive, and HVAC systems.

Investment in high-quality sheet metal roll forming machines and laser cutting machines is an investment in efficiency, precision, and long-term growth. Reliable equipment ensures that manufacturers can scale operations, produce consistent products, and respond to changing market demands. By partnering with experienced machine manufacturers, businesses gain access to cutting-edge technology, expert guidance, and after-sales support that safeguard their production capabilities.

In conclusion, advanced sheet metal roll forming machines and sheet metal laser cutting machines are essential for modern metal fabrication. Businesses seeking precision, efficiency, and high-quality output should work with trusted manufacturers to acquire machinery that meets production needs. Combining these technologies in one workflow enables faster, more accurate, and cost-effective manufacturing, supporting long-term success in the competitive metalworking industry.

-

Iron Sheet Laser Cutting Machine: Unmatched Precision for Demanding Fabrication with METMAC

2026/01/06 -

Precision Metal Cutting Machine: The Engine of Modern Manufacturing, Powered by METMAC

2026/01/06 -

Sheet Metal CNC Laser Cutting Machine: Precision Redefined with METMAC Technology

2026/01/06 -

Sheet Metal Press Brake for Sale: Find Your Precision Bending Solution with METMAC

2026/01/06

-

Advanced Sheet Metal Rolling, Laser Cutting, and Folding Machines for Precision Fabrication

2025/10/31 -

High-Performance Sheet Metal Bending and Cutting Machines for Modern Fabrication

2025/10/31 -

High-Quality Sheet Metal Equipment for Sale: Efficient Solutions for Modern Manufacturing

2025/10/31 -

High-Performance Sheet Metal Equipment for Sale: Forming and Shearing Solutions for Modern Fabrication

2025/10/22

-

A Guide to the Latest Innovations in Sheet Metal Folding Machines

2024/11/29 -

Key Features to Consider When Investing in a Sheet Metal Folding Machine

2024/11/28 -

Enhancing Precision with Advanced Sheet Metal Folding Machines

2024/11/27 -

How to Choose the Right Sheet Metal Folding Machine for Your Workshop

2024/11/26