Advanced Sheet Metal Processing with Laser Stainless Steel Cutting and Hydraulic Sheet Cutting Machines

- By:Metmac

- 2025-08-04

- 93

Efficient and precise metal fabrication is crucial in industries ranging from automotive to construction. Among the essential equipment for modern sheet metal processing are the laser stainless steel cutting machine, hydraulic sheet cutting machine, and sheet forming machine. Each plays a unique role in shaping metal components with accuracy and speed.

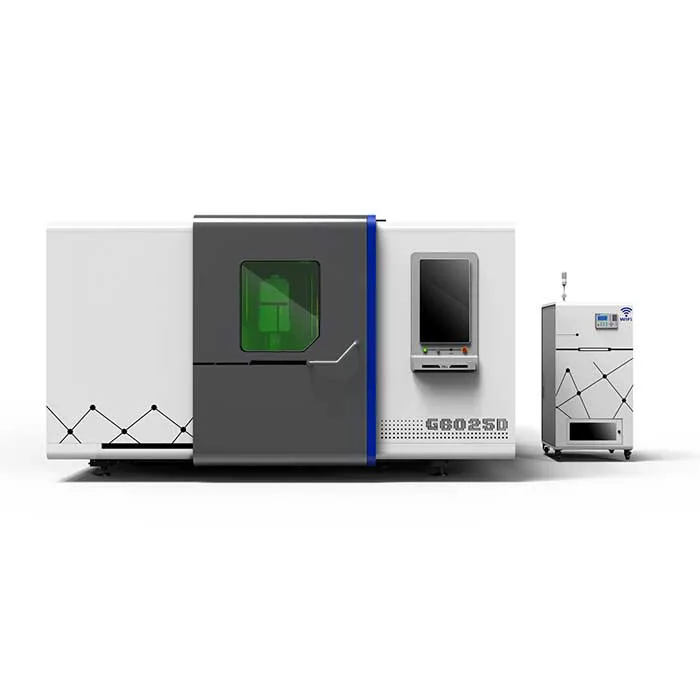

The laser stainless steel cutting machine is widely recognized for its high precision and clean cutting edges. Utilizing a focused laser beam, it vaporizes metal surfaces with minimal heat-affected zones, reducing deformation and ensuring intricate shapes can be cut effortlessly. This technology excels in cutting stainless steel sheets, delivering smooth edges without burrs and minimizing post-processing. Its automation capabilities enable consistent results even with complex designs, enhancing productivity and reducing material waste.

Complementing laser cutting technology, the hydraulic sheet cutting machine offers robust performance for heavy-duty metal cutting tasks. By applying hydraulic pressure, these machines shear thick metal sheets swiftly and accurately. Their mechanical simplicity combined with powerful cutting force makes them ideal for straight cuts on various metals, including steel and aluminum. These machines are favored in applications where high volume and durability are necessary, ensuring minimal maintenance and reliable operation over time.

Once sheets are cut to precise dimensions, the sheet forming machine comes into play to shape them into desired profiles or parts. Sheet forming encompasses bending, rolling, and pressing processes, transforming flat metal sheets into structural components like panels, channels, or complex curved shapes. Modern forming machines offer adjustable settings and programmable controls to accommodate different material thicknesses and shapes, resulting in consistent and repeatable forms tailored to production needs.

Integration of these machines within a manufacturing workflow streamlines the fabrication process. For example, raw stainless steel sheets are first precisely cut using laser technology to achieve detailed patterns or outlines. Larger or thicker sheets are then trimmed or segmented using hydraulic shears for initial shaping. Finally, sheet forming machines shape these cut pieces into functional parts that fit assembly requirements.

This synergy of technologies leads to increased efficiency, higher product quality, and reduced labor costs. It also enhances flexibility by allowing quick adjustments to design specifications without extensive tooling changes. As a result, manufacturers can meet tight deadlines and varying customer demands effectively.

Choosing the right equipment is vital for achieving optimal results. Factors such as sheet thickness, material type, production volume, and precision requirements influence machine selection. Manufacturers like those showcased on Metmac provide a diverse portfolio of laser cutting, hydraulic cutting, and forming machines tailored for diverse industrial needs.

In summary, combining the strengths of laser stainless steel cutting machines, hydraulic sheet cutting machines, and sheet forming machines forms a comprehensive solution for metal fabrication. These technologies empower manufacturers to deliver high-quality, precise components efficiently, supporting innovation and competitiveness in the metalworking sector.

-

Iron Sheet Laser Cutting Machine: Unmatched Precision for Demanding Fabrication with METMAC

2026/01/06 -

Precision Metal Cutting Machine: The Engine of Modern Manufacturing, Powered by METMAC

2026/01/06 -

Sheet Metal CNC Laser Cutting Machine: Precision Redefined with METMAC Technology

2026/01/06 -

Sheet Metal Press Brake for Sale: Find Your Precision Bending Solution with METMAC

2026/01/06

-

Advanced Sheet Metal Rolling, Laser Cutting, and Folding Machines for Precision Fabrication

2025/10/31 -

High-Performance Sheet Metal Bending and Cutting Machines for Modern Fabrication

2025/10/31 -

High-Quality Sheet Metal Equipment for Sale: Efficient Solutions for Modern Manufacturing

2025/10/31 -

High-Performance Sheet Metal Equipment for Sale: Forming and Shearing Solutions for Modern Fabrication

2025/10/22

-

Latest Technological Advancements in Rectangular Duct Machines

2024/05/11 -

Integrating Automation with Rectangular Duct Machines for Enhanced Productivity

2024/05/11 -

Metal Shear Machines- Essential Tools for Precision Metal Cutting

2024/05/11 -

Understanding the Role and Function of Steel Strip Slitting Machines

2024/05/11

-

A Guide to the Latest Innovations in Sheet Metal Folding Machines

2024/11/29 -

Key Features to Consider When Investing in a Sheet Metal Folding Machine

2024/11/28 -

Enhancing Precision with Advanced Sheet Metal Folding Machines

2024/11/27 -

How to Choose the Right Sheet Metal Folding Machine for Your Workshop

2024/11/26